5 Key Factors to Consider When Choosing an Industrial Plastic Enclosure

- Share

- publisher

- Suey

- Issue Time

- Aug 4,2025

Summary

From flame resistance to impact strength, selecting the right industrial plastic enclosure is crucial. This guide covers material types, certifications, and design features for optimal safety and performance.

5 Key Factors to Consider When Choosing an Industrial Plastic Enclosure

When selecting an industrial plastic enclosure, understanding its core features is essential to ensure the safety, performance, and durability of your equipment. Below are the five most important factors you should consider before making your choice.

1. Material Type and Durability

The material composition directly impacts the enclosure's strength and lifespan. Options like ABS, polycarbonate, and fiberglass-reinforced plastics each offer different levels of impact resistance, UV protection, and corrosion resistance. Choose a material that can handle your application’s environmental and mechanical demands.

2. Environmental Protection Ratings (IP/NEMA)

Environmental ratings indicate how well the enclosure protects against dust, moisture, and contaminants. For demanding industrial settings, consider enclosures with IP65, IP67, or equivalent NEMA ratings to ensure optimal performance even in harsh conditions.

3. Flame Retardant Properties

In industries where fire safety is critical, selecting a flame-retardant enclosure can prevent equipment damage and ensure compliance with safety regulations. Look for UL94 V-0 or similar fire-resistance certifications to guarantee reliable protection.

4. Customization Options

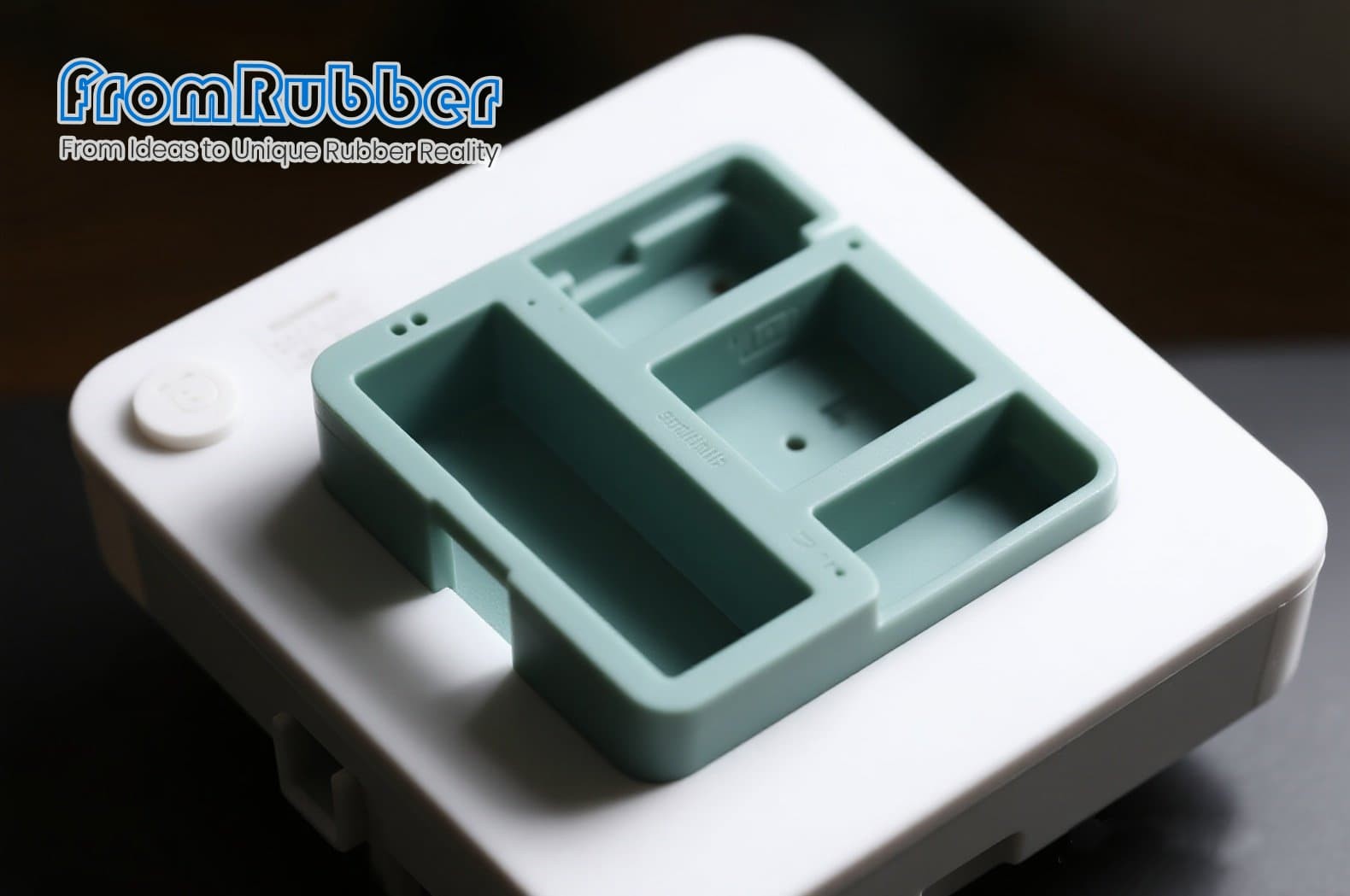

Every application has unique requirements. Choose a manufacturer that offers customization services such as CNC machining for cutouts, laser engraving for labels, or custom colors and finishes to match your brand and technical specifications.

5. Thermal Management Features

Electronics generate heat during operation, and excessive heat can reduce their lifespan. Select enclosures with ventilation slots, integrated heat sinks, or compatibility with cooling systems to keep internal components at safe temperatures.