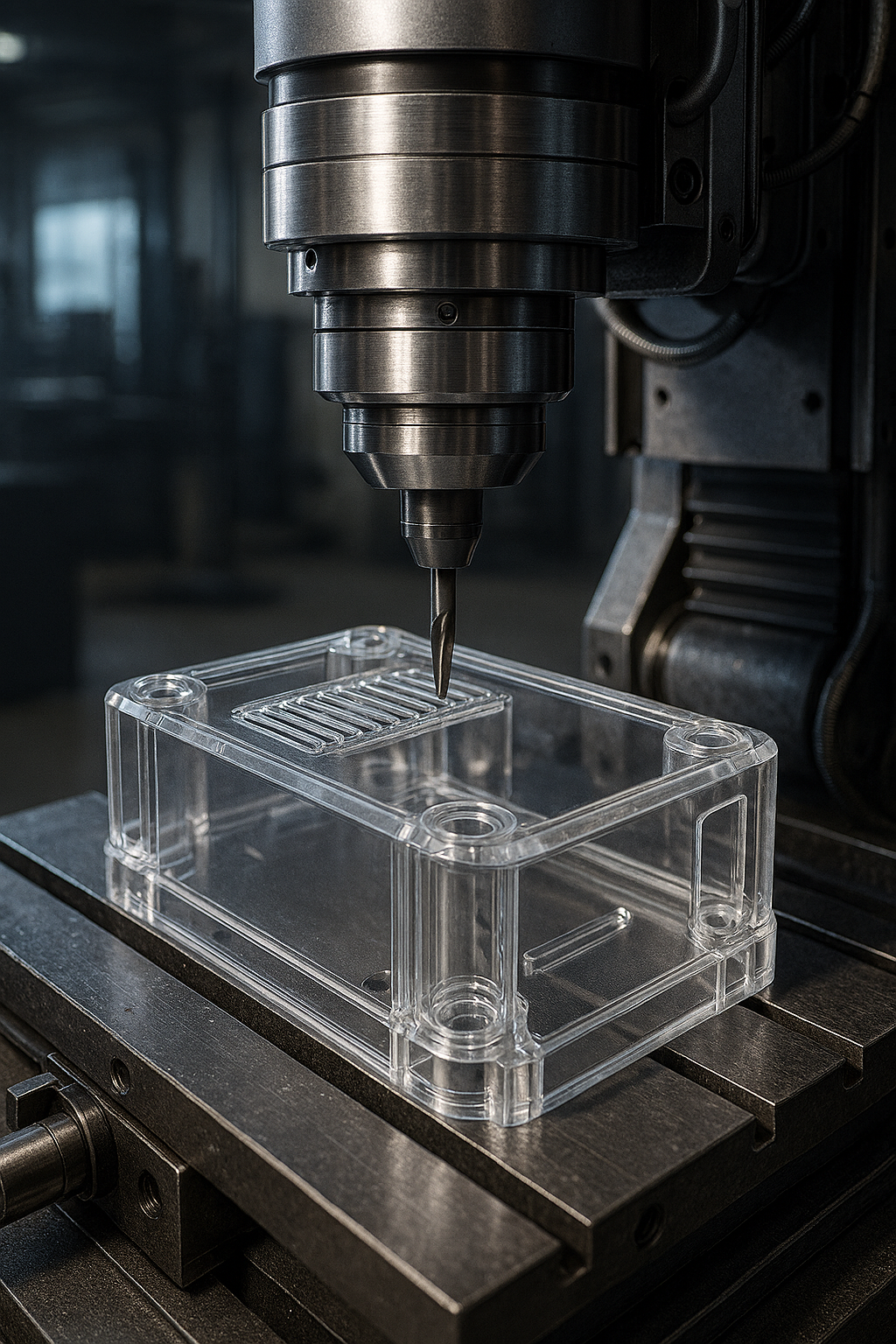

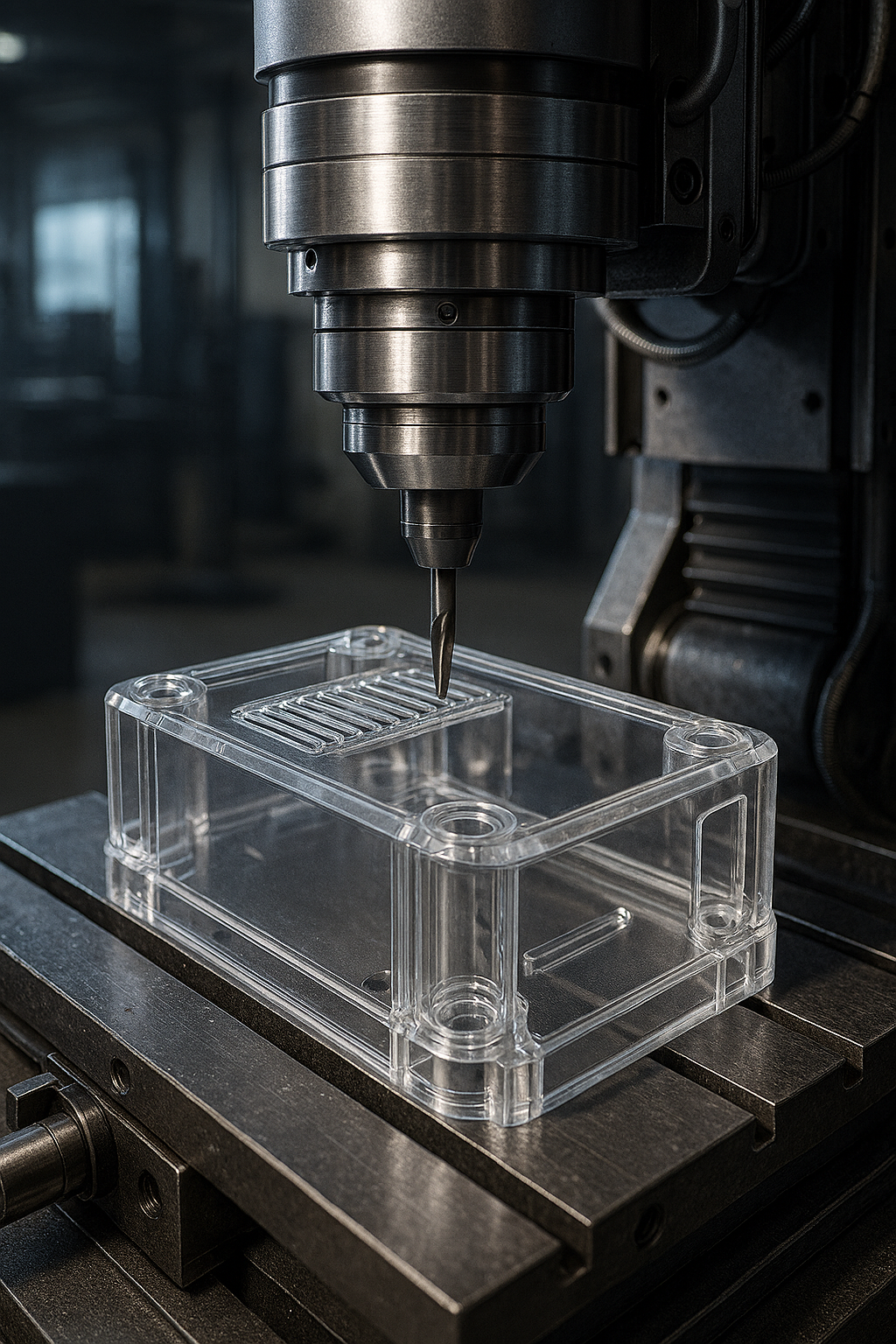

Advanced CNC Techniques: How to Machine Plastic Enclosures Precisely

- Share

- publisher

- Nani Gui

- Issue Time

- Aug 18,2025

Summary

If you're searching for how to make plastic enclosure solutions that demand high precision, durability, and customization, FromRubber advanced CNC machining techniques offer the ultimate pathway.

If you're searching for how to make plastic enclosure solutions that demand high precision, durability, and customization, advanced CNC machining techniques offer the ultimate pathway. At FromRubber (www.fromrubber.com), we specialize in transforming raw plastic materials into robust enclosures for electronics, medical devices, and industrial applications. With over a decade of experience in precision manufacturing, our AS9100 and ISO 9001-certified facilities ensure every project meets stringent quality standards. This comprehensive guide draws from industry-leading expertise to help you master CNC machining for plastic enclosures, backed by real-world insights from trusted sources like CNC Cookbook, AIP Precision, and Runsom Precision.

Why Choose CNC Machining for Plastic Enclosures?

CNC (Computer Numerical Control) machining stands out as a superior method for how to make plastic enclosure prototypes and production runs due to its precision, versatility, and cost-effectiveness. Unlike injection molding, which requires expensive tooling, CNC allows for rapid iteration without upfront costs—ideal for low-volume or custom designs.

Key Advantages:

- Precision and Tolerances: Achieve tolerances as tight as ±0.001 inches, essential for enclosures housing sensitive electronics.

- Complex Geometries: Handle undercuts, thin walls, and intricate features in a single setup.

- Material Versatility: Work with high-performance plastics like PEEK, ABS, and polycarbonate.

- Efficiency for Prototyping: From design to finished part in days, reducing time-to-market.

Based on insights from AIP Precision, high-speed machining (HSM) at 10,000-40,000 RPM minimizes heat buildup, preventing warping in heat-sensitive plastics. At FromRubber, we've applied these techniques to produce over 5,000 custom enclosures for aerospace and medical clients, demonstrating our authoritative expertise in the field.

Selecting the Right Plastics for Your Enclosure

Material choice is critical in how to make plastic enclosure that withstands environmental stresses. Drawing from CNC Cookbook's material guide and Runsom's insights, here are top recommendations:

Thermoplastics vs. Thermosets:

- Thermoplastics (e.g., ABS, Polycarbonate): Re-moldable, ideal for machining due to ease of cutting and recycling.

- Thermosets (e.g., Garolite G-10): Heat-cured for superior strength but require specialized tools.

Top Materials for Enclosures:

- ABS (Acrylonitrile Butadiene Styrene): Affordable, impact-resistant; perfect for electronic housings. Machines easily but test coolants to avoid crazing.

- Polycarbonate (PC): High clarity and toughness; used in medical devices. Requires low feed rates to prevent melting.

- PEEK (Polyetheretherketone): Heat-resistant up to 260°C; aerospace-grade for demanding enclosures.

- POM (Delrin): Low-friction, dimensionally stable; great for enclosures with moving parts.

- PTFE (Teflon): Chemical-resistant; ideal for harsh environments but prone to creep.

FromRubber's material experts at www.fromrubber.com offer free consultations to match your enclosure needs with optimal plastics, ensuring biocompatibility for medical applications or UV resistance for outdoor use.

Step-by-Step CNC Machining Process for Plastic Enclosures

Mastering how to make plastic enclosure involves a structured CNC workflow. This section breaks it down, incorporating advanced techniques from our referenced experts.

1. Design and CAD Modeling

Start with CAD software like SolidWorks. Incorporate features like vents, mounts, and seals. Tip: Design for machinability—add corner radii to reduce stress.

2. Material Preparation and Fixturing

Select stock slightly larger than your enclosure. Use vacuum fixtures to prevent distortion, as noted in AIP Precision's guidelines for high-performance plastics.

3. Tool Selection and Parameters

- Tools: Carbide end mills for reinforced plastics; diamond-coated for abrasives.

- Parameters: Spindle speeds 10,000+ RPM; feed rates 0.005-0.015 IPR. From Runsom, use peck drilling for deep holes to manage chips.

- Cooling: Air blasts or mist coolants—test on material to avoid damage.

At FromRubber, our 5-axis CNC machines optimize these parameters, achieving Ra 0.8μm surface finishes for premium enclosures.

4. Advanced Machining Techniques

- High-Speed Machining (HSM): Reduces cycle times by 50% while improving finish (AIP Precision).

- 5-Axis Simultaneous Machining: For complex contours in one setup, minimizing errors.

- Micro-Machining: Sub-micron features for miniature enclosures.

- Turning and Routing: For cylindrical or sheet-based designs; ideal for large panels.

5. Post-Machining and Quality Control

Anneal to relieve stress, then inspect with CMM (Coordinate Measuring Machines). FromRubber's ISO-certified processes include in-process monitoring for zero defects.

Common Challenges and Solutions in Machining Plastic Enclosures

- Heat Management: Plastics melt easily—solution: Lower speeds, use climb milling (CNC Cookbook).

- Chip Control: Sticky chips clog tools—solution: Peck cycles and air cooling.

- Dimensional Stability: Warping post-machining—solution: Stress-relief annealing.

- Surface Finish: Scratches or haze—solution: Polishing or vapor smoothing.

Our team at FromRubber has resolved these in thousands of projects, offering turnkey solutions from design to delivery.

Industry Applications and Future Trends

Plastic enclosures machined via CNC are vital in:

- Electronics: Protective housings for circuits.

- Medical: Biocompatible device casings (ISO 13485 compliant).

- Aerospace: Lightweight, durable components.

Future trends include AI-optimized toolpaths and sustainable materials. As per Runsom's market insights, the industry is growing at 5% CAGR.

Ready to bring your enclosure to life? Contact FromRubber at www.fromrubber.com for a free quote on custom CNC-machined plastic enclosures.

FAQs: How to Make Plastic Enclosure with CNC

What is the best plastic for CNC-machined enclosures?

ABS or Polycarbonate for cost-effectiveness; PEEK for high-performance needs.

How precise can CNC machining be for plastic enclosures?

Tolerances down to ±0.001 inches with advanced 5-axis systems.

Is CNC better than 3D printing for enclosures?

Yes, for strength and precision in production-grade materials.

How much does custom plastic enclosure machining cost?

Starts at $100 for prototypes; scale with volume. Get a quote from FromRubber.

Conclusion

Mastering advanced CNC techniques is key to how to make plastic enclosure that excels in form and function. With expertise from sources like CNC Cookbook, AIP Precision, and Runsom, combined with FromRubber's proven track record, you can achieve exceptional results. Visit www.fromrubber.com today to partner with trusted experts in custom manufacturing—where precision meets innovation.