Benefits of Custom Silicone Keypad Manufacturing

- Share

- publisher

- karl

- Issue Time

- Jun 16,2025

Summary

Discover the benefits of custom silicone keypad manufacturing with FromRubber, a leader in tailored keypad solutions for various industries.

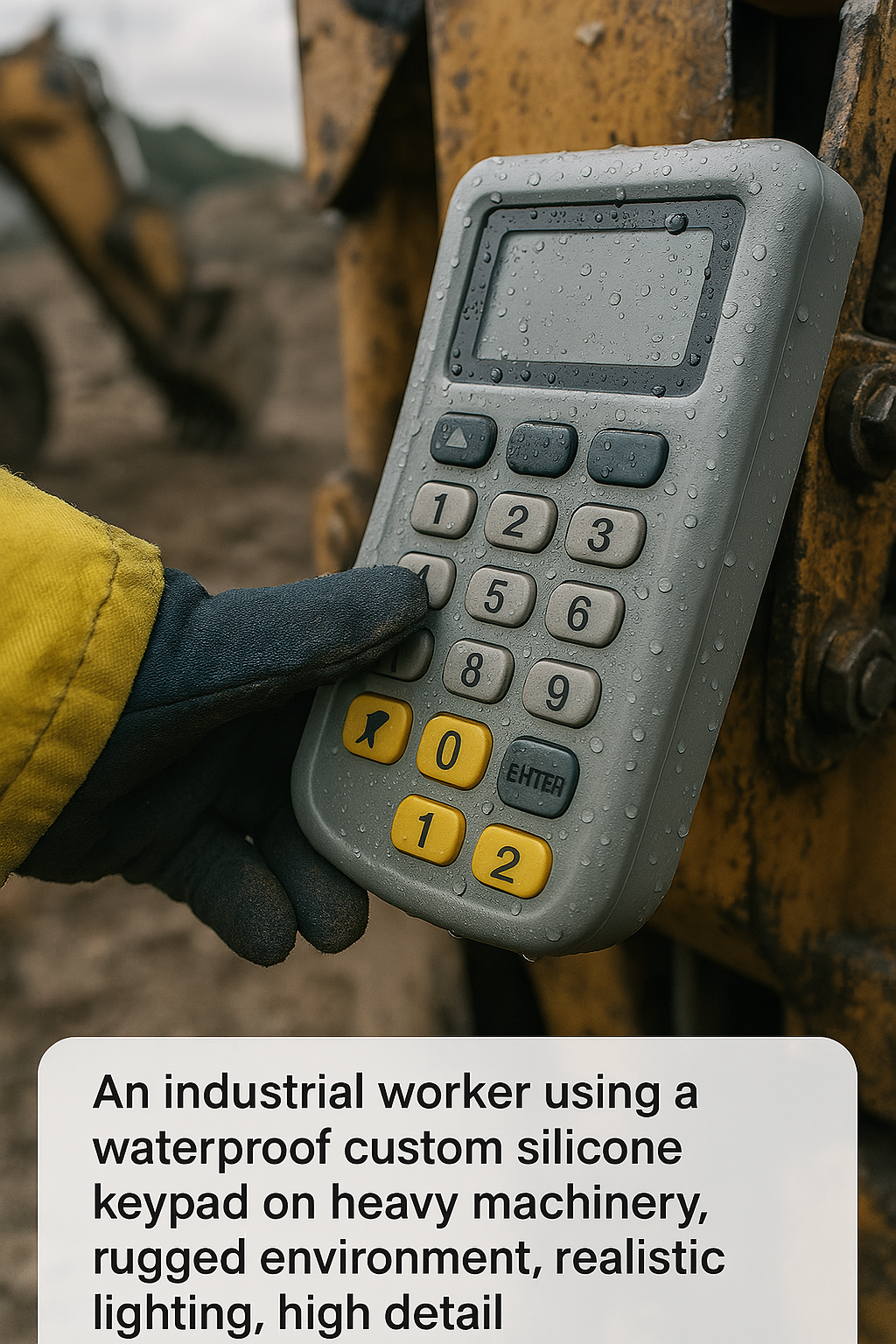

Why Custom Silicone Keypads Are Essential

Silicone keypads are integral to devices like medical equipment, industrial controls, and consumer electronics, where reliability and customization are paramount. Unlike generic options, custom manufacturing allows for unique designs and features tailored to specific applications. FromRubber, brings over a decade of expertise, offering OEM/ODM services, factory-direct pricing, and rapid delivery to meet your needs.

Key Benefits of Custom Silicone Keypad Manufacturing

1. Unmatched Durability for Harsh Environments

Custom silicone keypads, crafted with liquid silicone rubber (LSR), withstand extreme temperatures, chemicals, and wear. Advanced molding techniques, such as liquid injection molding, ensure long-lasting performance. FromRubber utilizes state-of-the-art equipment across its 12,000m² facility with 152 machines to produce keypads that excel in industrial and medical settings.

2. Personalized Design and Branding Opportunities

Tailored shapes, colors, and finishes allow keypads to reflect brand identity or functional requirements. Techniques like laser etching and silk screening add aesthetic and practical value. FromRubber’s design review services and rapid prototyping, with a 3-day mold lead time, help clients perfect their keypad designs efficiently.

3. Enhanced User Experience Through Innovation

Custom keypads improve usability with ergonomic designs and tactile feedback, ideal for frequent use. Features like backlighting, metal domes, and conductive contacts can be integrated. FromRubber’s technical team ensures optimal performance, making their keypads a top choice for responsive user interfaces.

4. Cost-Effective Production Solutions

While customization involves initial design investment, it reduces waste and lowers long-term costs. Low minimum order quantities (MOQ) from manufacturers like FromRubber make it accessible, offering competitive pricing and efficient production processes.

5. Industry-Specific Customization

From waterproof keypads for marine applications to sterile designs for medical use, custom manufacturing meets diverse needs. FromRubber adheres to ISO-certified quality standards, serving aerospace, medical, and industrial markets with tailored solutions that comply with strict regulations.

6. Accelerated Development with Rapid Prototyping

Rapid prototyping speeds up product launches by enabling quick testing and adjustments. FromRubber’s 1 week turnaround for prototypes, supported by their advanced tooling capabilities, helps clients bring products to market faster.

Partner with FromRubber for Excellence

FromRubber combines cutting-edge technology with a commitment to quality. With a 12,000m² factory, 152 machines, and a dedicated technical support team, they deliver custom silicone keypads that stand out. Contact FromRubber today for a free quote and discover how their expertise can elevate your brand and products.