Built to Fit, Built to Last: Why Custom Automotive Rubber Parts Make All the Difference

- Share

- publisher

- Suey

- Issue Time

- Jun 20,2025

Summary

Discover how custom automotive rubber parts improve performance, durability, and fit. FromRubber offers precision molding, CNC tooling, and expert engineering support for tailored rubber solutions in vehicles—from seals to mounts and isolators. Engineered for harsh environments, built to last.

Built to Fit, Built to Last: Why Custom Automotive Rubber Parts Make All the Difference

In the world of automotive design and repair, the smallest components often carry the greatest responsibility. A single gasket, mount, or seal—if not engineered correctly—can lead to costly breakdowns, performance issues, or safety concerns. That’s why vehicle manufacturers and aftermarket solution providers increasingly turn to custom rubber parts that are not just close to the right fit—they’re exact.

At high RPMs or in high-heat environments, generic parts often reveal their limits. Consider the case of a fleet maintenance team managing utility trucks across multiple climates—from the icy peaks of Colorado to the sweltering oil fields of Texas. After recurring failures in off-the-shelf rubber bushings, they shifted to tailored components made from oil-resistant FKM and high-durability silicone. The result? Extended service life, fewer replacements, and ultimately, reduced vehicle downtime.

Precision Is Power

Custom automotive rubber parts are not just about material—they’re about engineering precision. Whether you're retrofitting a suspension system for a race car or enhancing thermal protection around EV battery modules, accuracy in shape, thickness, and elasticity is non-negotiable.

Unlike standard parts designed to fit a wide range of models, customized components are created for your exact specifications—ensuring flawless installation and optimized performance. From heat-resistant turbocharger hoses to noise-dampening engine mounts, tailored rubber parts support modern vehicle designs that push the limits of power, temperature, and pressure.

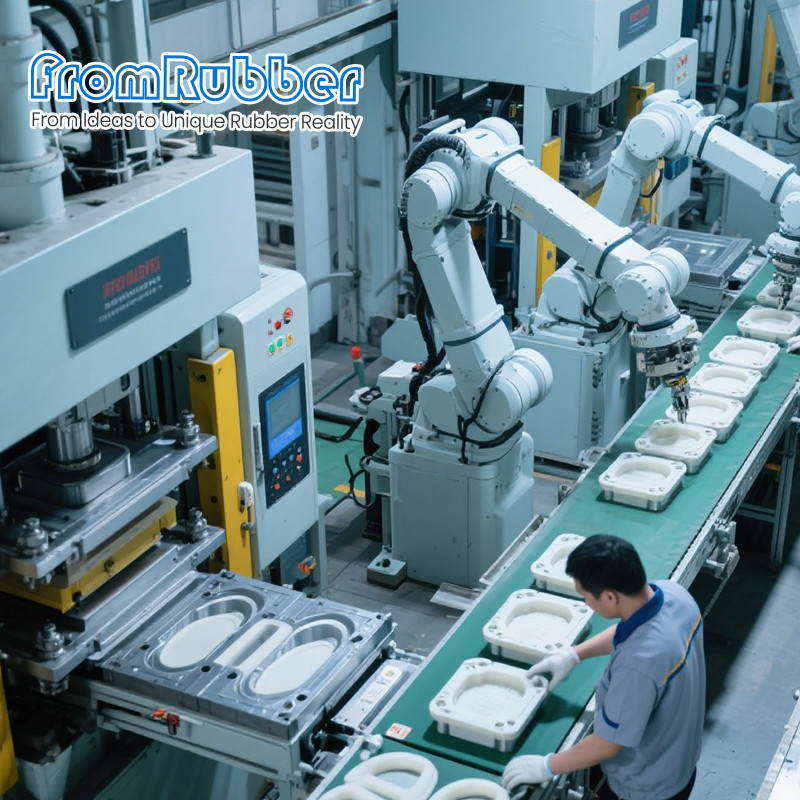

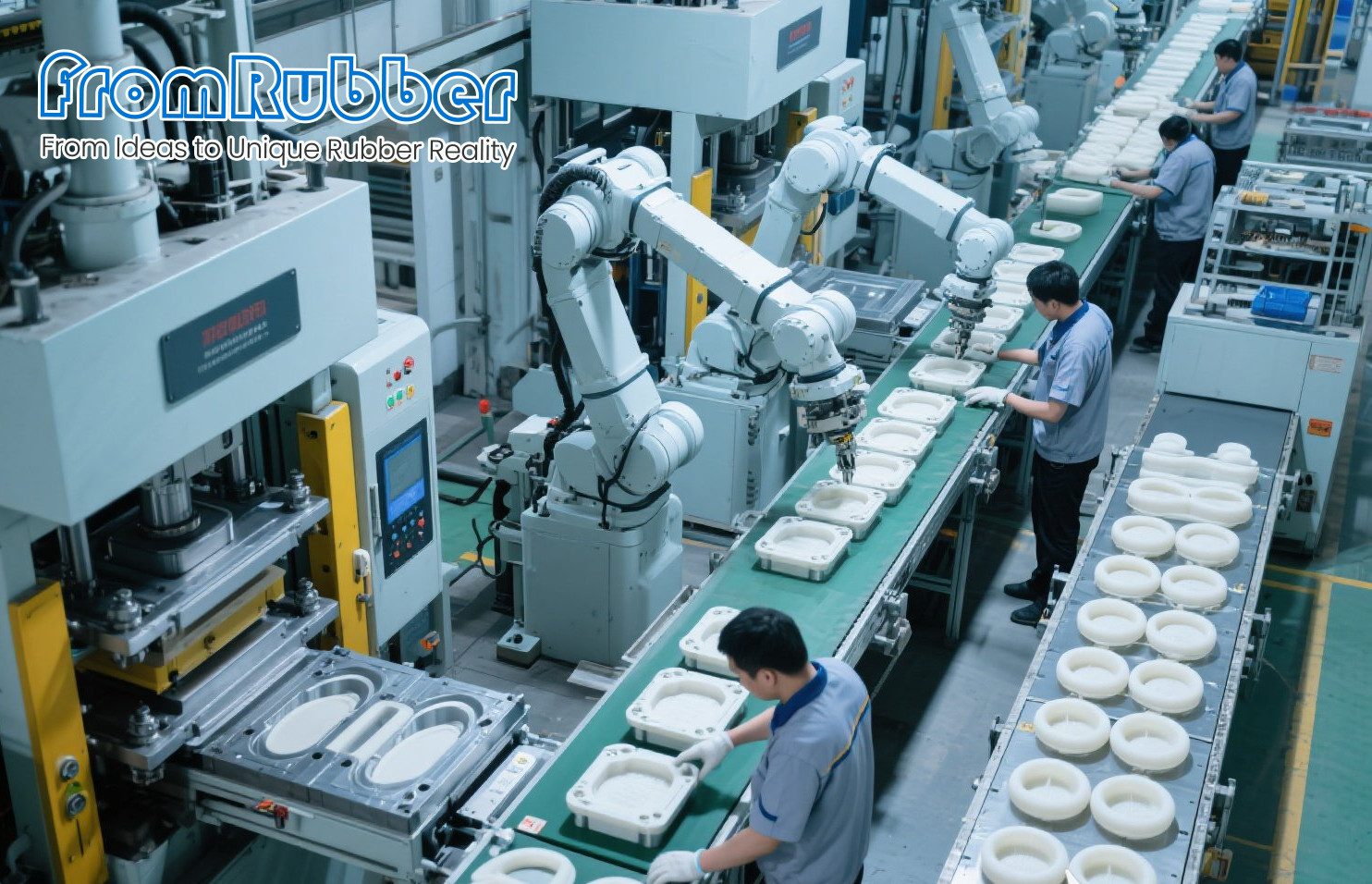

Inside the Manufacturing Powerhouse

Delivering on such precision demands more than just good intentions—it requires infrastructure. At FromRubber, every custom order is backed by:

- 40 compression molding machines capable of producing high-precision parts with tight tolerances.

- 10 CNC machining stations for intricate tooling and post-processing needs.

- Free engineering consultations to help customers identify the best materials and optimize part geometry before production begins.

This capacity allows FromRubber to respond quickly, even for complex parts with multi-material interfaces or challenging sealing surfaces. And with in-house tooling, prototyping doesn’t require long wait times or third-party vendors.

Customization That Works in the Real World

Let’s say a heavy-equipment manufacturer needs rubber isolators for a new series of excavators. These isolators must perform under constant vibration, mud, and hydraulic fluid exposure. Off-the-shelf parts won’t cut it—not for field equipment that’s expected to work 12 hours a day, every day.

FromRubber’s engineers consult directly with the design team, recommending a custom EPDM blend with increased ozone resistance. Molds are developed in-house, and pilot samples are delivered within days. Once approved, full-scale production begins—with every piece matching the original specification, batch after batch.

Designed for Durability, Scaled for Growth

What sets a quality rubber parts supplier apart isn’t just the ability to produce—it’s the ability to scale production without sacrificing quality. Every batch of FromRubber’s parts undergoes mechanical stress testing, dimensional inspection, and environmental simulation before being delivered.

Whether you're producing 1,000 specialized hose connectors or 500,000 weatherproof gaskets, consistency is key—and customization makes it possible.

FromRubber: Your Custom Rubber Partner

Every vehicle component plays a role in safety, efficiency, and reliability. That’s why every part you use should be engineered for your needs—not someone else's.

FromRubber is trusted by automotive innovators across industries, from EV startups to commercial fleet operators. With advanced manufacturing capacity, hands-on technical support, and a relentless commitment to quality, we help transform design ideas into production-ready components that perform under pressure.

Let your next part be the perfect one—custom-built with FromRubber.