Custom Plastic Injection Molding: Process and Benefits with Fromrubber Expertise

- Share

- publisher

- Nani Gui

- Issue Time

- Jul 8,2025

Summary

Custom plastic injection molding is a cornerstone of modern manufacturing, enabling businesses to create precise, high-quality plastic parts tailored to their needs. At Fromrubber, we specialize in delivering innovative customs plastics solutions, combining advanced technology with decades of expertise to meet the demands of industries like automotive, medical, and consumer goods.

Custom Plastic Injection Molding: Process and Benefits with Fromrubber Expertise

Introduction to Custom Plastic Injection Molding

Custom plastic injection molding is a cornerstone of modern manufacturing, enabling businesses to create precise, high-quality plastic parts tailored to their needs. At Fromrubber, we specialize in delivering innovative customs plastics solutions, combining advanced technology with decades of expertise to meet the demands of industries like automotive, medical, and consumer goods. This guide explores the injection molding process, its benefits, and why partnering with an experienced manufacturer like Fromrubber ensures success for your custom projects.

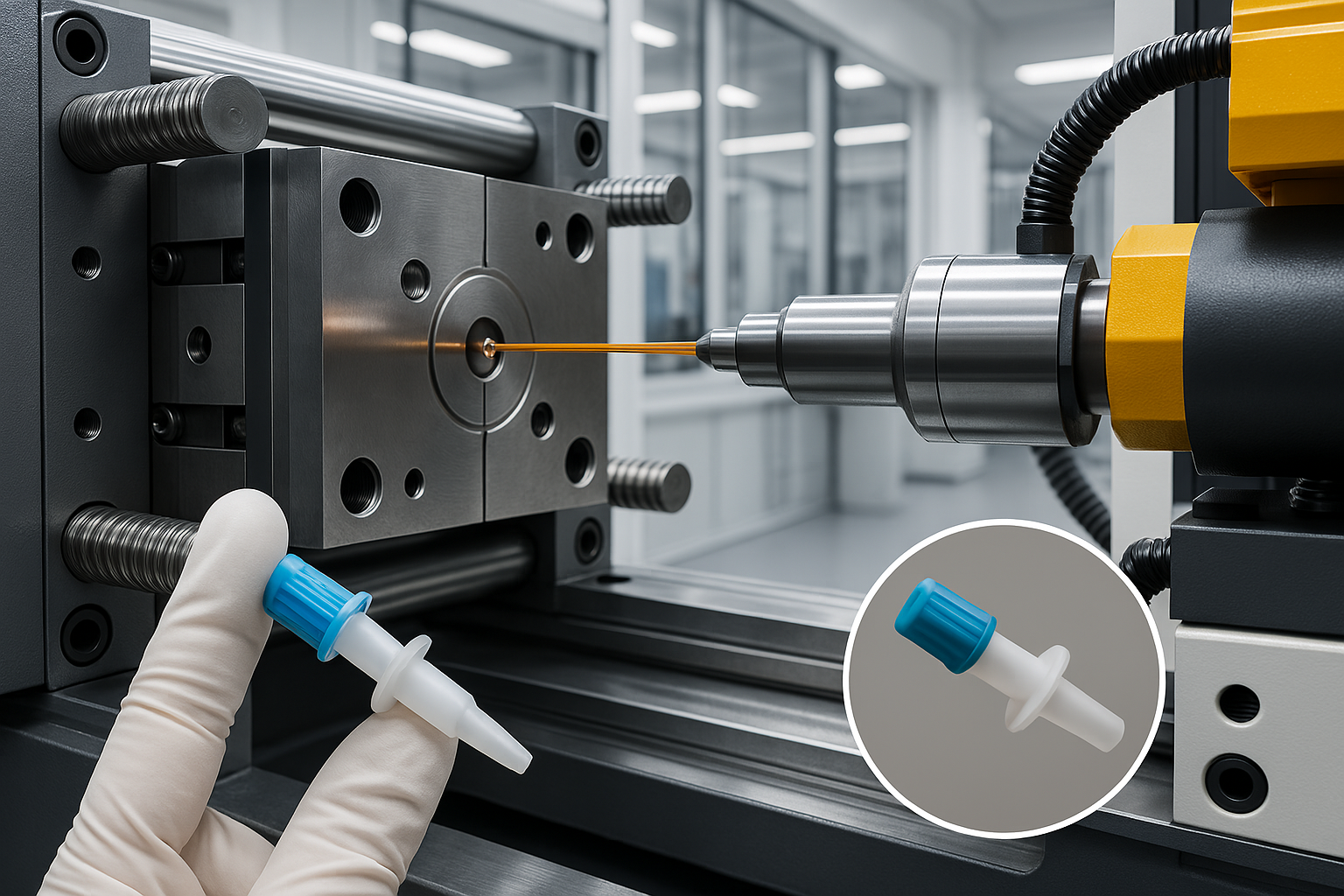

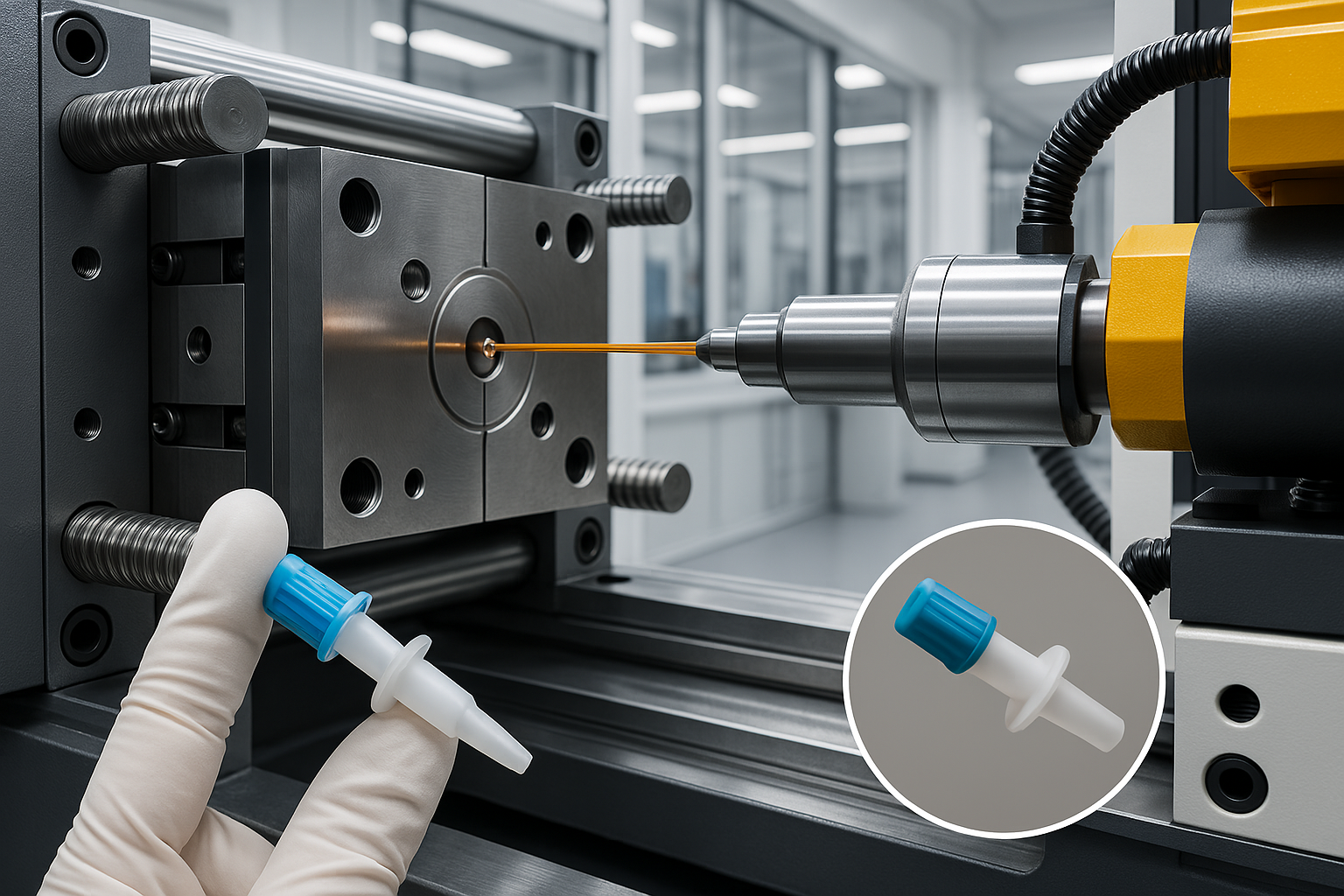

What is the Custom Plastic Injection Molding Process?

Injection molding is a highly efficient process for producing complex plastic parts with tight tolerances. Here’s a step-by-step breakdown of how Fromrubber delivers customs plastics solutions:

-

Design and Tooling:

- A CAD model of the desired part is created, adhering to design principles like uniform wall thickness and draft angles to ensure moldability.

- A precision mold, typically made from steel or aluminum, is CNC-machined to form the negative of the part.

- At Fromrubber, our engineers use advanced DFM (Design for Manufacturability) analysis to optimize designs, reducing costs and production time.

-

Material Feeding:

- Thermoplastic pellets (e.g., ABS, polycarbonate, or recycled resins) are loaded into a hopper.

- Fromrubber offers a wide range of materials, including sustainable options, to meet project-specific requirements.

-

Melting and Injection:

- Pellets are fed into a heated barrel, where a reciprocating screw melts and mixes the plastic.

- The molten plastic is injected under high pressure (100-150 MPa) into the mold cavity through a runner system and gates.

-

Cooling and Solidification:

- The mold is cooled to solidify the plastic, ensuring the part retains its shape with minimal defects like sink or warp.

- Fromrubber uses scientific molding techniques to maintain consistent cooling and part quality.

-

Ejection:

- Once solidified, the mold opens, and ejector pins remove the finished part.

- The process repeats rapidly, enabling high-volume production with cycle times as low as 15-120 seconds.

Key Benefits of Custom Plastic Injection Molding

Custom plastic injection molding offers unmatched advantages for businesses seeking customs plastics solutions. Here’s why it’s the preferred choice for high-volume manufacturing:

-

High Precision and Repeatability:

- Tolerances as tight as ±0.003 inches ensure parts meet exact specifications, ideal for industries like medical and aerospace.

- Consistent quality across millions of parts, as noted by Plastics Engineering’s 2023 market analysis valuing the industry at $270 billion.

-

Cost-Effectiveness for High Volumes:

- While initial tooling costs range from $3,000 to $100,000, the per-unit cost drops significantly for large runs, often $1-5 per part, making it ideal for mass production.

- Fromrubber offers flexible order quantities, including low-volume prototyping, to suit diverse needs.

-

Material Versatility:

- Choose from thousands of thermoplastics, including ABS, polycarbonate, PEEK, and recycled resins, to match performance requirements like strength or UV resistance.

- Fromrubber provides expert material selection guidance to optimize durability and sustainability.

-

Design Flexibility:

- Create complex geometries, from intricate medical devices to automotive components, with features like ribs, bosses, and snap-fit joints.

- Our team at Fromrubber supports advanced processes like overmolding and insert molding for enhanced functionality.

-

Sustainability and Low Waste:

- Minimal material waste, with excess plastic (e.g., sprues or defective parts) recyclable for future runs.

- Fromrubber prioritizes eco-friendly practices, using up to 98% recycled materials for select projects.

-

Fast Production Cycles:

- Cycle times of 15-120 seconds enable rapid production, reducing time-to-market for your customs plastics products.

Applications of Custom Plastic Injection Molding

Custom plastic injection molding serves a wide range of industries, delivering customs plastics solutions for diverse applications:

- Automotive: Dashboards, bumpers, and lightweight interior components that improve fuel efficiency.

- Medical: Sterile, precise components like syringes, surgical tools, and diagnostic device housings.

- Consumer Goods: Durable, aesthetically pleasing products like packaging, electronics enclosures, and toys.

- Aerospace: Lightweight, high-strength parts like turbine blades and chassis components, often made with PEEK for low flammability.

- Telecommunications: Robust housings for cell phones, routers, and infrastructure components.

Case Study: Fromrubber partnered with a leading medical device manufacturer to produce 100,000 syringe barrels using ABS resin. Our scientific molding approach ensured ±0.001-inch tolerances, reducing defects by 99% and cutting production time by 20%.

Why Choose Fromrubber for Your Customs Plastics Needs?

At Fromrubber, we combine 30 years of expertise with cutting-edge technology to deliver superior customs plastics solutions. Here’s what sets us apart:

- Certified Expertise: ISO 9001 and AS 9100 certified, ensuring compliance with the highest quality standards.

- Advanced Technology: State-of-the-art injection molding machines and AI-driven process optimization for efficiency and precision.

- Sustainability Commitment: Use of recycled materials and eco-friendly practices to minimize environmental impact.

- Customer-Centric Approach: From free DFM consultations to rapid prototyping, we tailor solutions to your needs, with no minimum order requirements.

- Global Compliance: Expertise in navigating customs plastics regulations, including import/export duties and recycling policies, ensuring seamless logistics.

Testimonial: “Fromrubber transformed our product development with their expertise in injection molding. Their team delivered high-quality parts on time, helping us meet tight deadlines.” – John Doe, Product Manager, MediTech Solutions.

Navigating Customs Regulations for Plastics

For businesses involved in global trade, understanding customs plastics regulations is critical. Customs duties on plastics vary by material and country (e.g., India’s recent duty reductions on PVC resin). Fromrubber offers compliance support, ensuring your plastic products meet international standards for import/export and recycling. Our logistics team partners with trusted freight forwarders to streamline shipping and customs clearance.

How to Get Started with Fromrubber

Ready to bring your customs plastics project to life? Follow these steps:

- Submit Your Design: Upload your CAD file for a free DFM analysis.

- Choose Materials: Work with our experts to select the ideal resin for your application.

- Get a Quote: Receive a detailed quote within 24 hours, with transparent pricing.

- Production and Delivery: Benefit from our fast turnaround and global shipping capabilities.

CTA: Contact Fromrubber today for a free consultation or upload your design for an instant quote. Let us help you create high-quality customs plastics solutions tailored to your needs.

About Fromrubber

Founded in 2010, Fromrubber is a leader in customs plastics manufacturing, serving