Custom Rubber Patches Durable Design Options and Ordering Guide

- Share

- publisher

- karl

- Issue Time

- Sep 10,2025

Summary

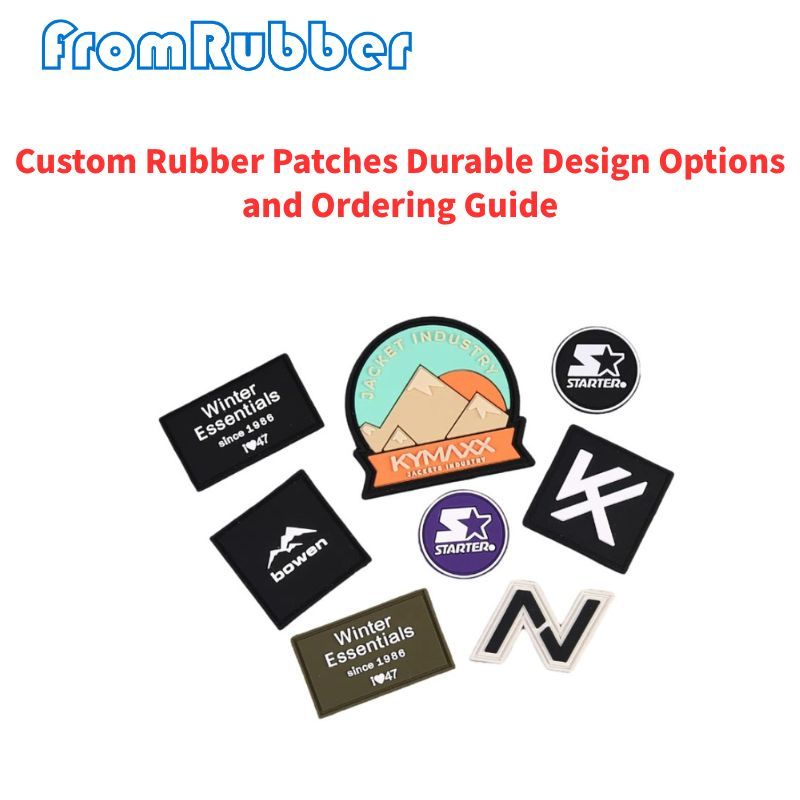

Get durable custom rubber patches with flexible designs perfect for branding apparel gear and promotional use from expert manufacturers.

1. What Are Custom Rubber Patches

Custom rubber patches are personalized labels made from flexible, durable materials like silicone, PVC, or TPU. Unlike woven or embroidered patches, rubber patches have a smooth, raised surface and often feature intricate, 3D designs. They don't fray or fade, making them tougher and more versatile.

| Feature | Rubber Patches | Woven Patches | Embroidered Patches |

|---|---|---|---|

| Material | Silicone, PVC, TPU | Thread and fabric | Thread and fabric |

| Texture | Smooth, raised, 3D effects | Flat, detailed | Raised with thread loops |

| Durability | High (waterproof, weatherproof) | Moderate | Moderate |

| Flexibility | Very flexible | Less flexible | Moderate |

| Colors | Bright, vibrant, Pantone matched | Limited by thread colors | Limited by thread colors |

| Maintenance | Easy to clean | Can fray and fade | Requires gentle care |

Rubber patches stand out because they are waterproof, weather-resistant, and flexible. They hold up well outdoors or on tough gear, making them perfect for everything from outdoor apparel to tactical equipment. This makes them a go-to for anyone needing a durable, long-lasting patch that won't lose its sharp look.

2. Why Choose Custom Rubber Patches

Custom rubber patches offer strong branding and marketing benefits. They make logos and designs stand out with vibrant colors and sharp details. This visibility helps your brand get noticed on apparel, bags, hats, and more.

They're also super practical. You'll find them on safety gear, sportswear, backpacks, and promotional items because they hold up well under rough use and outdoor conditions.

Customization options are wide open. You can pick any color, shape, size, and texture—including cool 3D effects—that fit your brand's style perfectly.

Rubber patches last longer than woven or embroidered ones. Thanks to materials like silicone or PVC, they resist water, sun, and wear better, keeping your design looking fresh for years.

| Feature | Custom Rubber Patches | Woven/Embroidered Patches |

|---|---|---|

| Color Vibrancy | High, precise matches (Pantone) | Limited by thread colors |

| Durability | Weatherproof, flexible | Prone to fading, fraying |

| Custom Shapes | Any shape, 3D textures | Mostly standard shapes |

| Attachment Options | Sew-on, adhesive, Velcro | Mainly sew-on |

| Longevity | 5+ years with use | 1-2 years under heavy wear |

3. Design Options for Custom Rubber Patches

When it comes to custom rubber patches, FromRubber offers plenty of design choices to fit your needs. Here's what you can expect:

3.1 Color Matching and Pantone Integration

- Exact color matching using Pantone standards

- Vivid, lasting colors ideal for branding and logos

- Multi-color options with sharp detail

3.2 Shapes and Sizes

FromRubber can craft patches in:

- Simple geometric shapes (circles, squares, rectangles)

- Custom, intricate shapes matching your logo or design

- Sizes ranging from small logos to large patches for jackets or bags

3.3 Surface Textures

| Texture Type | Description | Best For |

|---|---|---|

| Soft-touch | Smooth and flexible | Apparel, comfortable wear |

| Raised 3D | Detailed, embossed elements | Logos and badges |

| Glossy | Shiny, bright finish | Eye-catching designs |

| Matte | Flat, non-reflective surface | Subtle, professional look |

3.4 Attachment Methods

Flexibility extends to how you attach the patch:

- Sew-on: Classic, secure option

- Iron-on: Quick, no-sew application

- Adhesive backing: Peel-and-stick for easy use

- Velcro: Removable and reusable

- Snap buttons: For detachable customization

These options make custom rubber patches from FromRubber versatile across apparel, accessories, and gear, fitting any style or function you might need.

4. The Custom Rubber Patch Manufacturing Process at FromRubber

At FromRubber, we start with an initial consultation where you submit your design ideas. This helps us understand your vision and requirements clearly.

Next, we create prototypes for your review. You get to approve samples before we move forward, ensuring the final product matches your expectations.

We source high-quality materials like silicone, PVC, or TPU, depending on your patch's needs. Using advanced molding techniques, we shape patches that are flexible, durable, and detailed.

Finally, every patch goes through strict quality control and testing. This guarantees your custom rubber patches hold up in real-world use and maintain precise design elements throughout their lifespan.

5. Applications and Use Cases of Custom Rubber Patches

Custom rubber patches are incredibly versatile, fitting into many different industries and uses across the U.S. Here's where they really stand out:

-

5.1 Apparel and Fashion

Great for jackets, hats, shoes, and backpacks, custom rubber patches add style and personality while holding up against everyday wear.

-

5.2 Military and Tactical Gear

Their durability and weather resistance make rubber patches ideal for uniforms, tactical vests, and gear that needs to last in tough conditions.

-

5.3 Outdoor Equipment and Camping Gear

Waterproof and flexible, these patches work well on tents, backpacks, and other outdoor items that face rough environments.

-

5.4 Corporate Branding and Event Giveaways

Custom rubber patches are a popular go-to for businesses wanting unique, durable swag. They catch attention at trade shows, company events, and promotional campaigns.

-

5.5 Repair and Protective Patches for Industrial Uses

Rubber patches can reinforce or cover worn areas on tools, gear, or protective clothing, extending the life of equipment in industrial settings.

6. How to Order Custom Rubber Patches from FromRubber

Ordering custom rubber patches from FromRubber is simple and straightforward. Here's how it works:

-

6.1 Step-by-step Process

Contact us: Reach out through our website or by phone to start your project.

Design submission: Send your artwork or ideas. If you need help, we offer design support.

Quote and approval: Get a clear price and timeline. Approve the sample before production.

Production: Once approved, we start manufacturing with quality control at every step.

Delivery: Receive your custom patches on time, ready to use.

Minimum order quantities and bulk pricing: We offer flexible minimum orders to fit small or large needs. Bulk orders come with cost savings, making it affordable whether you need a handful or thousands of patches. -

6.2 Shipping and Delivery

FromRubber ships across the United States with fast, reliable service and also supports global deliveries. We handle logistics so your patches arrive safely and on schedule.

-

6.3 Customer Support and Customization Assistance

Our team is here to guide you through design choices, material options, and attachment methods. We make sure your custom rubber patches fit your exact needs and brand vision.

Ordering from FromRubber means getting durable, high-quality rubber patches with service that's clear and hassle-free.

7. Tips for Designing Effective Custom Rubber Patches

When creating custom rubber patches, keep these tips in mind to make sure your design works well and lasts.

7.1 Maintain Branding Consistency

- Use your official logos and color schemes to keep your patch recognizable.

- Match colors with Pantone codes if you want exact brand colors.

7.2 Choose the Right Size and Shape

- Pick a size that fits the item the patch will go on—too big or small can look off.

- Simple shapes often work better for visibility and durability, but custom shapes add a unique touch.

7.3 Select the Best Backing and Attachment

- Decide between sew-on, iron-on, adhesive backing, Velcro, or snap buttons based on how you'll use the patch.

- For outdoor gear, Velcro or sew-on is usually more secure. For promo items, adhesive backing might be more convenient.

7.4 Think About Durability and Environment

- If the patch will face sun, rain, or rough use, choose materials and finishes that resist fading, cracking, or peeling.

- Opt for rubber patches with weather-resistant qualities like silicone or PVC for long-lasting wear.

Keeping these factors in check helps your custom rubber patch look sharp and last longer, making it a smart addition to your apparel or gear.

8. Frequently Asked Questions About Custom Rubber Patches

8.1 What is the typical production lead time?

Most custom rubber patch orders take about 2 to 3 weeks from design approval to shipping. Rush orders may be available but usually come with extra fees.

8.2 Can I get patches with reflective or glow-in-the-dark materials?

Yes, we offer options like reflective PVC and glow-in-the-dark additives for visibility and unique effects, perfect for safety gear or promotional items.

8.3 How do I care for and clean custom rubber patches?

Cleaning is simple—just use mild soap and water. Avoid harsh chemicals or machine washing with strong detergents to keep patches looking fresh and durable.

8.4 Are eco-friendly or recycled material options available?

We're moving toward greener choices and can provide patches made from recycled PVC and silicone upon request. Just ask about eco-friendly options when placing your order.

Get Your Custom Rubber Patches Today!

Transform your brand with durable, vibrant, and fully customizable rubber patches from FromRubber.

Start Your Order Now