How to Choose the Right Liquid Silicone Protective Cover for Medical Equipment

- Share

- publisher

- Suey

- Issue Time

- Jun 13,2025

Summary

Selecting the appropriate silicone protective cover for medical equipment is crucial for ensuring device longevity, patient safety, and compliance with industry standards. Medical liquid silicone covers, known for their biocompatibility, flexibility, and durability, are increasingly vital in healthcare settings. This guide will walk you through the key factors to consider when choosing the right cover, helping you make an informed decision for your medical devices.

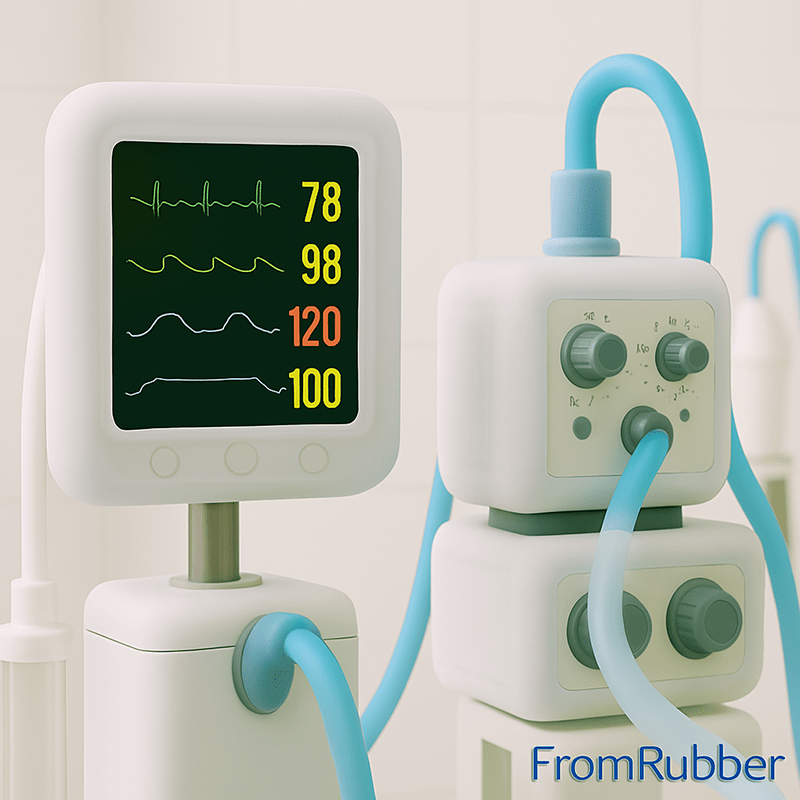

Why Liquid Silicone Protective Covers Matter for Medical Devices

Silicone protective covers offer critical protection for medical devices, shielding them from contamination, wear, and environmental damage while maintaining functionality. Medical-grade liquid silicone rubber (LSR) is ideal due to its hypoallergenic properties, high-temperature sterilization compatibility, and ease of cleaning. These qualities make it perfect for devices like catheters, infusion pumps, and diagnostic tools. Choosing the right cover enhances device performance and ensures patient safety and comfort.

Key Factors in Choosing a Liquid Silicone Protective Cover

1. Biocompatibility and Safety

Safety is paramount in medical applications. Medical-grade silicone must meet stringent standards like FDA and ISO 10993 to prevent adverse patient reactions. Advanced platinum-cured silicone ensures no harmful byproducts, offering top-tier biocompatibility for skin or fluid contact.

2. Device Compatibility

Each medical device has unique design and operational needs. The cover must match the device’s shape, size, and usage requirements. For instance, precision devices like endoscopes require custom-fit covers for seamless integration.

3. Sterilization Compatibility

Frequent sterilization is common in medical settings. Silicone covers must withstand autoclaving, ethylene oxide (ETO), or gamma radiation without degrading. High thermal stability and chemical resistance are essential for long-term reliability.

4. Durability and Flexibility

A quality silicone cover should resist tearing, abrasion, and chemical exposure while remaining flexible for easy installation and use. Low-viscosity liquid silicone achieves this balance, ensuring durability in demanding environments.

5. Customization Options

Customization meets specific needs, such as color coding, branding, or unique functionality. Advanced mold-making capabilities allow for tailored designs that align with device specifications and brand identity.

Steps to Select the Right Liquid Silicone Cover

- Identify device needs: Assess type and usage environment.

- Verify material standards: Ensure medical-grade certification.

- Collaborate with experts: Seek tailored recommendations.

- Test fit: Confirm no interference with device operation.

- Evaluate longevity: Check durability and maintenance needs.

Conclusion

Selecting the right silicone protective cover involves evaluating biocompatibility, compatibility, sterilization resistance, durability, and customization. A well-chosen cover ensures device safety and performance, making it a vital investment in medical care.

Are you ready to protect your medical equipment? Contact a silicone expert to explore a customized solution that suits your needs!

Contact Now