How to Design Custom Conductive Silicone Buttons

- Share

- publisher

- karl

- Issue Time

- Jun 18,2025

Summary

Explore FromRubber's custom conductive silicone buttons, and you'll get professional knowledge and custom solutions.

Welcome to the ultimate guide on designing custom conductive silicone buttons, brought to you by FromRubber, a trusted leader in silicone and rubber product manufacturing since 1995. With over two decades of expertise, FromRubber specializes in creating high-quality, durable conductive silicone buttons tailored to your specific needs. Whether you're designing for electronics, medical devices, or consumer products, this blog will walk you through the process with insights grounded in industry best practices.

Introduction to Custom Conductive Silicone Buttons

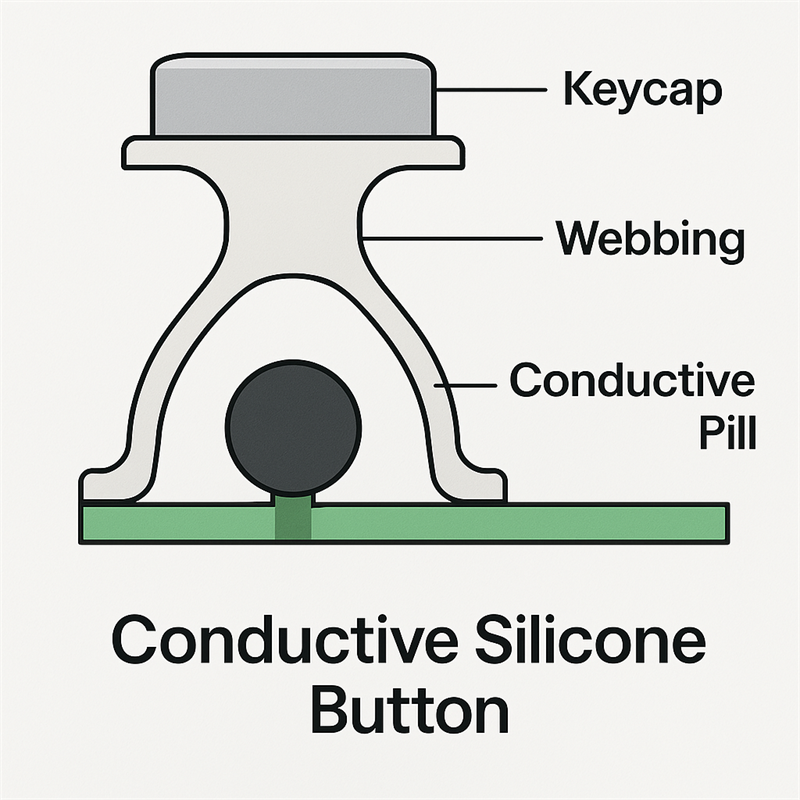

Conductive silicone buttons are essential components in modern electronic devices, offering a blend of flexibility, durability, and reliable conductivity. These buttons use conductive materials like carbon pills or metal domes to complete circuits when pressed, making them ideal for keypads, remote controls, and more. At FromRubber, we pride ourselves on delivering custom solutions that meet the highest standards, ensuring your designs stand out in the market.

- Why Customize? Tailored designs enhance functionality and aesthetics, aligning with your brand’s unique requirements.

- Applications: From automotive dashboards to gaming controllers, conductive silicone buttons are versatile and widely used.

Step-by-Step Design Process

Define Your Requirements

Start by identifying the purpose and environment of your buttons. Consider factors like actuation force, travel distance, and resistance to heat or moisture—key aspects highlighted in industry resources. FromRubber’s team of experts can assist you in selecting the right specifications to match your project’s demands, drawing on our extensive experience with diverse applications.

- Key Considerations:

- Actuation Force: Typically 180-250g for optimal tactile feedback.

- Travel Distance: 0.2-0.4mm for effective webbing deformation.

- Environmental Factors: Ensure resistance to dust and liquids.

Material Selection

Choose the right silicone compound and conductive material. Options include carbon pills for cost-effectiveness or metal domes for enhanced reliability, as noted in leading design guides. FromRubber offers a range of materials, including high-grade silicone rubber, to ensure longevity and performance tailored to your needs.

- Conductive Options:

- Carbon Pills: Affordable and widely used.

- Metal Domes: Higher conductivity, ideal for precision devices.

- Silicone Hardness: Adjustable to balance flexibility and firmness.

Design the Button Structure

The button structure includes the keycap, webbing, and conductive contact. Webbing design is critical for tactile response, with a 45° angle and 0.2-0.4mm thickness being standard for optimal performance. FromRubber’s state-of-the-art molding technology allows for precise customization, ensuring each button meets your exact design.

- Components:

- Keycap: Aesthetic and ergonomic design.

- Webbing: Controls actuation force and return.

- Conductive Contact: Ensures circuit completion.

Incorporate Surface Treatments

Enhance durability and appearance with surface treatments like PU coating or laser etching for backlit designs. FromRubber’s advanced coating processes, including wear-resistant PU, protect your buttons from wear while allowing for custom logos or symbols, boosting your brand visibility.

- Options:

- PU Coating: Improves wear resistance.

- Laser Etching: Ideal for translucent, backlit buttons.

- Screen Printing: Adds custom graphics.

Prototyping and Testing

Create prototypes to test functionality and tactile feel. FromRubber offers low MOQ prototyping services, allowing you to refine designs before full production. Our rigorous testing ensures each button meets industry standards for conductivity and durability.

- Testing Focus:

- Tactile Feedback: Verify snap ratio (40-60% recommended).

- Conductivity: Confirm consistent circuit closure.

- Durability: Assess lifecycle under repeated use.

Manufacturing with FromRubber

Once your design is finalized, FromRubber’s manufacturing process leverages compression molding and insert molding techniques to produce high-quality conductive silicone buttons. Located in the heart of the industry, our facility in China combines cutting-edge technology with a skilled workforce, ensuring efficient production and cost savings. Visit our web to learn more about our capabilities and request a quote today.

- Process Highlights:

- Compression Molding: For precise shapes and conductivity.

- Insert Molding: Integrates conductive pills seamlessly.

- Quality Assurance: Adheres to strict industry standards.

Tips for Success

- Collaborate with experts like FromRubber to optimize your design.

- Balance cost and performance by selecting appropriate conductive materials.

- Test prototypes in real-world conditions to ensure reliability.

Conclusion

Designing custom conductive silicone buttons is a rewarding process that combines creativity with technical precision. With FromRubber as your partner, you gain access to unparalleled expertise and customized solutions that elevate your products. Start your project today by contacting us at "About Us" for a consultation.