Rubber Overmolding: A Smarter Way to Unite Plastic & Metal

- Share

- publisher

- Suey

- Issue Time

- Jul 3,2025

Summary

Discover how rubber overmolding can transform your plastic or metal components into high-performance parts with enhanced grip, sealing, and durability. Perfect for OEMs seeking cost-effective, ergonomic, and scalable solutions, this process eliminates secondary assembly and boosts product value—ideal for automotive, electronics, and industrial use.

What is Rubber Overmolding and Why It Matters

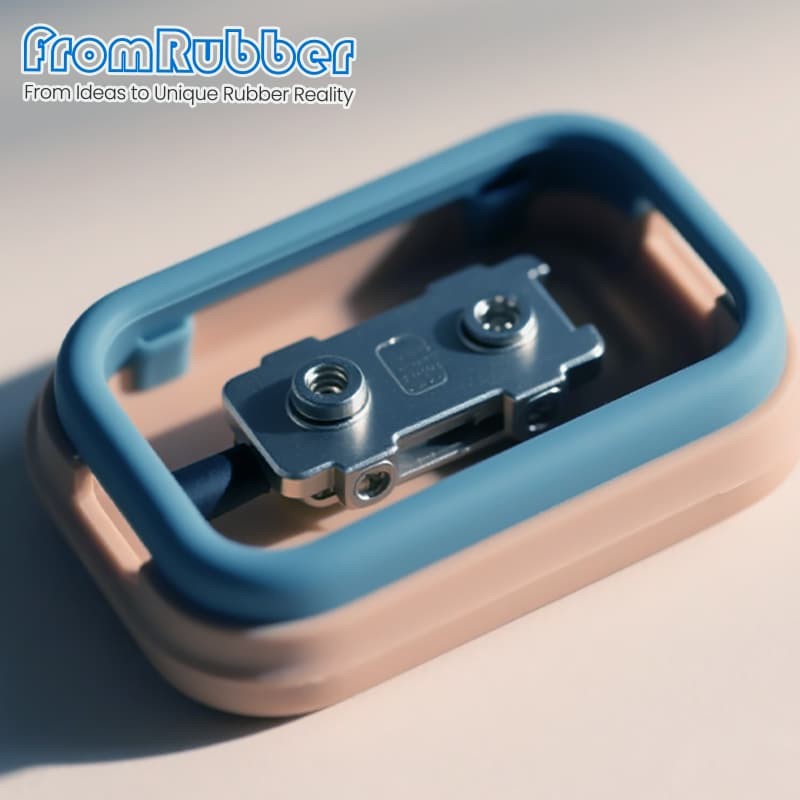

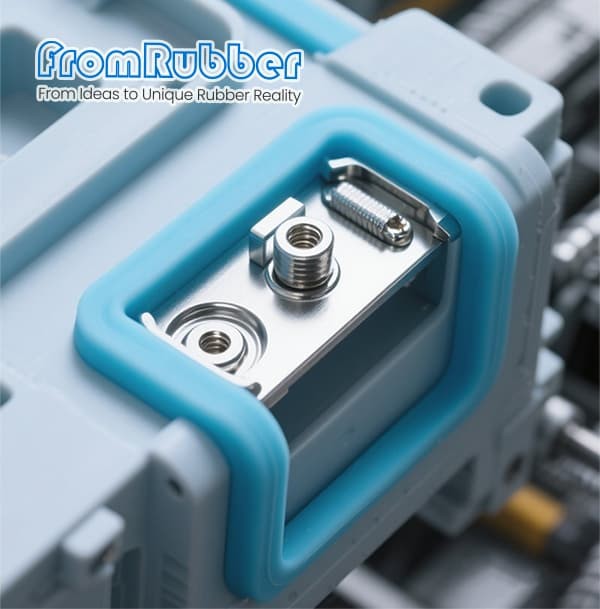

Rubber overmolding is a sophisticated one-piece molding process that permanently bonds a flexible rubber layer onto a rigid plastic or metal substrate. This integrated manufacturing method produces components with exceptional structural integrity, eliminating weak joints and mechanical fasteners that often fail under stress.

The result is a highly durable, wear-resistant part that withstands harsh mechanical vibrations, thermal cycling, and environmental exposure. This seamless fusion not only enhances the product’s lifespan but also improves ergonomic comfort, sealing performance, and noise damping—making it ideal for automotive, medical, electronics, and industrial applications.

By adopting one-piece overmolding, manufacturers benefit from reduced assembly steps, lower production costs, and improved quality control, delivering high-precision parts with consistent performance.

Key Advantages of Rubber Overmolding

Superior Bond Strength

One-piece molding creates a chemical and mechanical bond that is stronger and more durable than traditional adhesives or mechanical fasteners, ensuring long-term product reliability.

Enhanced Product Durability

Eliminates failure points by removing assembly seams, improving resistance to wear, thermal expansion, vibration, and environmental factors.

Cost-Effective Manufacturing

Reduces assembly labor and tooling complexity, supports high-volume scalable production with consistent quality and customizable material options.

Where Rubber Overmolding Is Used

From rugged industrial devices to sleek consumer electronics, rubber overmolding adapts across industries where safety, comfort, and durability are critical. Its ability to create a waterproof, slip-resistant, and vibration-dampening surface makes it ideal for:

- ● Automotive knobs, handles, shift levers

- ● Power tools & construction equipment

- ● Medical instruments & diagnostic devices

- ● Consumer electronics & handhelds

- ● Outdoor sports gear & smart wearables