Silicone Rubber Keypad Design Guide for Durable Tactile Performance

- Share

- publisher

- karl

- Issue Time

- Oct 16,2025

Summary

Discover expert silicone rubber keypad design tips including material selection tactile feedback molding techniques and custom solutions for durable keypads.

1. Understanding Silicone Rubber Keypads Basics and Key Components

When you're designing a silicone rubber keypad, it's important to start with the basics. These keypads are made from flexible elastomeric materials that give you durability and a great tactile feel. At their core, silicone rubber keypads consist of three main parts:

- ●Silicone rubber dome: This creates the spring action you feel when pressing a button. It offers excellent tactile feedback and bounce-back.

- ●Carbon pill or conductive element: Placed under each key, this conductive material completes the electrical circuit when pressed, sending your command to the device.

- ●Backing or PCB integration: The keypad sits on a printed circuit board (PCB) where the electrical signals are processed.

Understanding these components helps you design keypads that are responsive, reliable, and user-friendly. Silicone's natural flexibility and resistance to extreme temperatures and chemicals make it perfect for both indoor and outdoor devices. Plus, its ability to absorb shocks and resist wear ensures a long-lasting product.

FromRubber Pro Tip: Always consider how the key shapes and spacing affect user comfort and response time. Clear layouts and consistent tactile feedback can really improve the overall experience.

2. Material Selection and Properties for High Performance Keypads

Choosing the right materials is crucial when designing silicone rubber keypads that perform well and last long. Silicone rubber is popular because it's flexible, durable, and can handle a wide temperature range—perfect for many US industries. When selecting materials, focus on these key aspects:

-

2.1 Shore Hardness

The hardness rating affects how the keypad feels and responds. Softer silicone (lower Shore) offers easy pressing but less durability, while harder silicone (higher Shore) is tougher and resists wear but requires more force. Finding the right balance ensures comfortable tactile rubber switch design and reliable use.

-

2.2 Conductive Ingredients

For keypads that need electrical response, conductive silicone with carbon pill actuation is common. This mix allows for short, clean electrical signals when you press a button, essential for crisp keypad PCB integration.

-

2.3 Dual-Durometer Molding

Some designs use dual-durometer silicone rubber keypads, combining softer and harder areas in one part. This method improves tactile feedback while keeping the form durable and flexible.

-

2.4 Environmental Resistance

Pick materials that resist moisture, dust, and chemicals to protect your keypad in real-world settings. Environmental sealing for keypads is especially important for devices exposed to harsh conditions outdoors or in industrial environments.

-

2.5 Compatibility with Printing Methods

Silicone keypads often need sharp, durable graphics. Choosing materials that work well with laser-etched graphics keypad techniques or screen printing helps maintain clear symbols over time.

By paying attention to these properties, you can build a keypad that feels great, works reliably, and meets the high standards expected from a top silicone keypad supplier or rubber buttons manufacturer serving the US market.

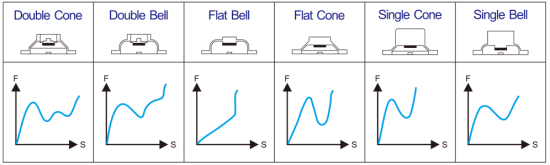

3. Designing Tactile Feedback and Actuation Getting the Feel Right

When it comes to silicone rubber keypad design, getting the tactile feedback just right is crucial. Users want a keypad that feels responsive without requiring too much force. The key is balancing actuation force, travel distance, and feedback quality.

Here's what you need to focus on:

- ●Carbon pill actuation: This is the conductive element beneath the button that completes the circuit when pressed. Proper placement and size ensure reliable signal without extra effort.

- ●Shore hardness selection: Silicone's flexibility affects the feel. A softer rubber (lower Shore hardness) means easier presses, but too soft can feel mushy. A harder rubber offers more resistance and feedback but could tire users.

- ●Travel distance and snap ratio: Shorter travel distances let users press faster. The snap, or "click" feeling, helps confirm input without needing to look at the keypad.

- ●Dual-durometer molding: Combining two rubber hardness levels can deliver firm feedback and soft comfort where needed. This technique improves usability and durability.

- ●Tactile rubber switch design: The shape and thickness of domes or buttons affect how the keypad feels. Dome height, base thickness, and overall layout all play a role.

Ultimately, the goal is a keypad that is easy to use for extended periods, reducing finger fatigue without losing reliability. We work closely with clients to tailor tactile feedback based on their specific needs, making sure every press feels natural and consistent.

In the U.S. market, where users expect quality on gadgets, industrial controls, or medical devices, nailing the feel of your silicone keypad is a game-changer.

4. Manufacturing Processes From Concept to Compression Molding

Bringing a silicone rubber keypad from an idea to a finished product involves several key steps, with compression molding being the most common method in elastomeric keypad manufacturing. Here's how it typically goes:

-

4.1 Prototype Development

First, we create prototypes to test the design. This helps nail the tactile rubber switch design and actuation feel. Early models let us adjust the Shore hardness and key spacing before full production.

-

4.2 Tooling and Mold Creation

Next, custom molds are made for compression molding. These molds must hold tight compression molding tolerances to ensure consistent keypad quality and durability.

-

4.3 Material Preparation and Mixing

Silicone rubber compounds, often with additives like carbon pills for conductive silicone buttons, are mixed and prepared based on the desired keypad performance.

-

4.4 Compression Molding Process

The silicone mix is placed into the mold and cured under heat and pressure. This step forms the keypad's exact shape, including any dual-durometer rubber molding parts if needed to provide varied key feels or stiffness.

-

4.5 Post-Molding Finishing

After molding, keypads may go through graphic printing—like laser-etched graphics keypad processes—and finishing touches such as environmental sealing to protect the keypad from moisture and dust.

-

4.6 Assembly and Testing

Finally, many silicone keypads are integrated with a keypad PCB to complete the product. Each unit is tested for tactile response, electrical performance, and durability before shipping.

Choosing a manufacturer familiar with these steps ensures a smooth transition from your concept to a reliable silicone rubber keypad product built for the US market.

5. Advanced Features Backlighting Graphics and Customization

When designing silicone rubber keypads, adding advanced features like backlighting and custom graphics can really boost usability and style. Backlit silicone keyboards help users operate devices in low-light conditions, making them perfect for everything from medical equipment to industrial controls. We often use LED backlighting combined with transparent or translucent silicone layers to achieve even light distribution.

Graphics are just as important. Laser-etched graphics on the keypad surface provide sharp, durable markings that won't wear off over time. Alternatively, printed or molded-in graphics give you options for colors and textures that match your brand or application. Customization also includes dual-durometer rubber molding, where softer and harder silicone sections are combined to improve feel and durability.

For carbon pill actuation, we embed conductive silicone buttons underneath keypads, which ensures reliable electrical contact and tactile response. And environmental sealing is key if your keypad faces harsh conditions, ensuring dust, water, and grease won't affect performance.

To sum up, these advanced features make your keypad not just a button pad, but a fully tailored interface ready for real-world challenges.

6. Quality Control Testing and Common Design Mistakes to Avoid

When designing silicone rubber keypads, quality control is crucial to ensure your product performs well and lasts long. Testing helps catch issues early and keeps production on track.

6.1 Key Quality Control Tests for Silicone Keypads

- ●Tactile feedback test: Verifies the feel and responsiveness of tactile rubber switch design so users get the right actuation.

- ●Durability testing: Simulates repeated pressing cycles to ensure the keypad withstands everyday use without wear or failure.

- ●Compression molding tolerances check: Confirms the molded parts meet size and fit requirements, preventing assembly or keypad PCB integration problems.

- ●Environmental sealing test: Checks for resistance to dust, moisture, and temperature changes, which is key for outdoor or industrial keypad applications.

- ●Electrical testing: Verifies conductive silicone button circuits, including carbon pill actuation, function correctly without short circuits or connectivity issues.

- ●Graphic durability test: Ensures laser-etched graphics on the keypad stay clear and don't fade with use or cleaning.

6.2 Common Design Mistakes to Avoid

- ●Ignoring Shore hardness selection: Using silicone that's too soft or too hard can ruin tactile feedback or durability. Choose a balanced elastomer for your specific use.

- ●Overcomplicating tactile designs: Complex switch shapes can increase costs and reduce reliability. Stick to proven tactile rubber switch designs.

- ●Poor compression molding tolerances: Tight tolerances are necessary. Loose fits can cause key wobble; too tight makes assembly difficult.

- ●Skipping environmental sealing: If your keypad faces moisture or dust, lack of sealing can lead to failure. Always incorporate proper sealing methods for your environment.

- ●Neglecting keypad PCB integration: Design the keypad layout and contacts to match your PCB perfectly. Misalignment leads to faulty keys.

- ●Underestimating graphic finishing: Avoid cheap printing methods that fade fast. Go for laser-etched or durable graphics to keep the keypad looking professional.

By focusing on these testing steps and avoiding common pitfalls, you ensure your silicone rubber keypads deliver the reliability and feel customers expect—especially important for US markets that require quality and consistency.

7. Applications and Case Studies Real World Success with Silicone Keypads

Silicone rubber keypads are everywhere in the United States—from industrial controls to consumer electronics. Their durability, flexibility, and easy customization make them a top choice for many industries. Here are some real-world examples where silicone keypads have made a difference:

7.1 Medical Devices

Healthcare equipment needs buttons that respond reliably and resist harsh cleaning chemicals. Silicone rubber keypads with carbon pill actuation provide consistent tactile feedback and environmental sealing, ensuring long-lasting performance.

7.2 Consumer Electronics

From remote controls to gaming devices, silicone keypads offer a soft feel and quiet operation. Backlit silicone keyboards customize the user experience, improving visibility in low-light settings. Laser-etched graphics keep the keypad looking fresh, even after heavy use.

7.3 Industrial Equipment

In tough environments, keypads must withstand dust, moisture, and extreme temperatures. Silicone keypads with high shore hardness and dual-durometer rubber molding deliver rugged construction without sacrificing tactility.

7.4 Automotive Controls

Drivers rely on keypad controls that are responsive and durable. Elastomeric keypad manufacturing techniques enable precise compression molding tolerances, producing consistent, long-lasting buttons that integrate smoothly with keypad PCBs.

These case studies prove how silicone rubber keypads adapt to diverse needs. Whether you're designing a custom silicone keypad for harsh industrial use or a consumer-friendly device, choosing the right materials and manufacturing methods is key to success.

If you want to explore how these solutions can fit your project, partnering with a Silicone Keypad Supplier experienced in the US market will give you the edge you're looking for.

8. Partnering with FromRubber for Custom Silicone Rubber Keypad Solutions

When you need reliable custom silicone rubber keypad solutions, partnering with FromRubber is a smart move. They specialize in elastomeric keypad manufacturing and offer flexible capabilities tailored to your project's needs. Whether it's a simple tactile rubber switch design or an advanced backlit silicone keyboard with PCB integration, FromRubber has the experience to deliver.

Here's what makes FromRubber stand out:

- ●Custom Silicone Keypad Design: They work with you from initial concept through compression molding, ensuring your keypad meets performance and durability goals.

- ●Material Expertise: FromRubber helps with shore hardness selection and can handle dual-durometer rubber molding for improved tactile feedback.

- ●Advanced Features: Need laser-etched graphics or carbon pill actuation? They've got it covered with precise manufacturing tolerances.

- ●Quality and Testing: Expect thorough quality control testing and environmental sealing options to keep your keypad working in tough conditions.

- ●Made for the US Market: Their processes are optimized to meet local demand and quality expectations, making them an ideal silicone keypad supplier in the United States.

Working with FromRubber means clear communication, quick turnaround, and products that fit your use case. Whether you're a small business or a large OEM, FromRubber delivers custom conductive silicone buttons and rubber buttons manufactured to your specs. If you want a partner who understands silicone keyboard factory demands and can guide you through the entire design and production process, FromRubber is ready to help.

Ready to Elevate Your Keypad Design?

Partner with FromRubber today for custom silicone solutions that deliver unmatched performance.

Get Your Free Quote Now