The Role of Conductive Keypads In Industrial Applications

- Share

- publisher

- karl

- Issue Time

- Jun 23,2025

Summary

Discover the role of conductive keypads in industrial applications with FromRubber's durable, customizable solutions.

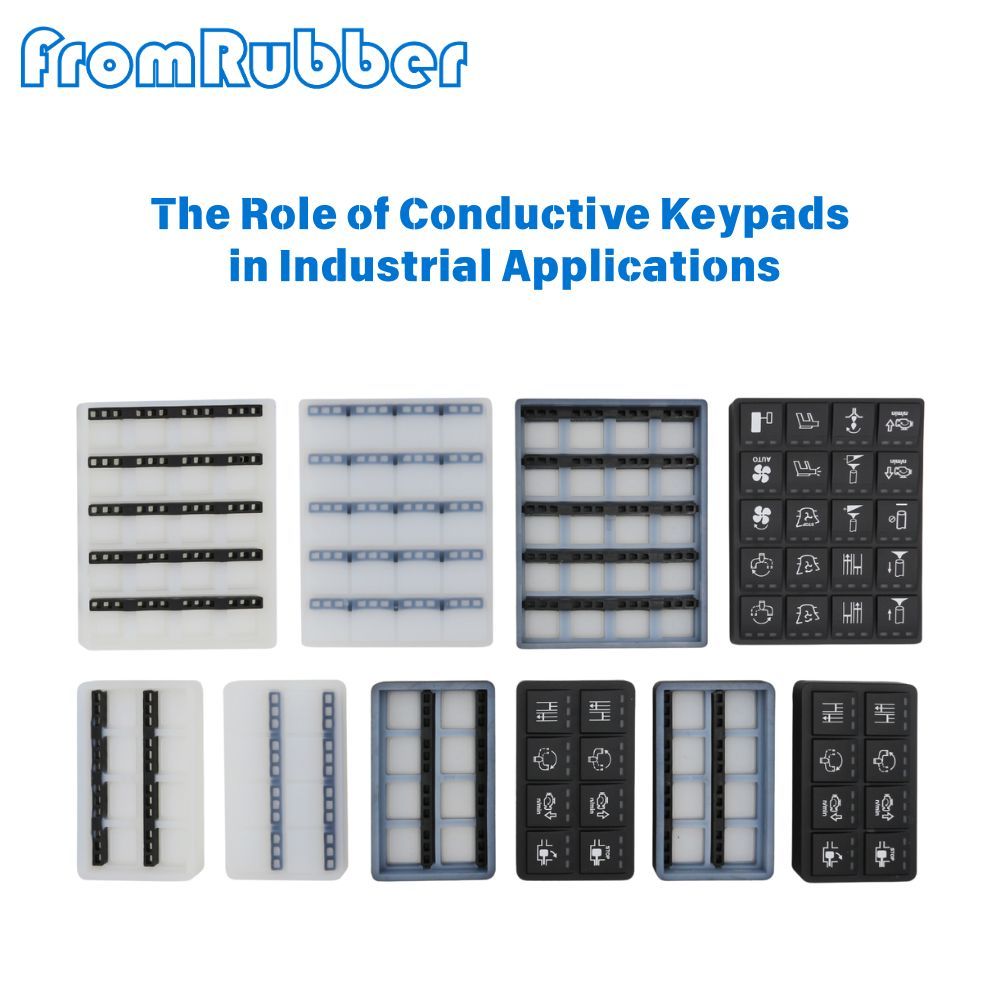

Conductive keypads, particularly those made from silicone rubber, are integral to modern industrial applications, offering durability, reliability, and customization for harsh environments. At FromRubber, we specialize in designing and manufacturing high-quality conductive keypads tailored to industrial needs, ensuring seamless human-machine interaction. This blog explores the critical role of conductive keypads in industrial settings, their key features, applications, and how FromRubber's expertise delivers innovative solutions.

Why Conductive Keypads Are Essential for Industrial Environments

Industrial environments demand robust, reliable, and user-friendly interfaces. Conductive keypads, leveraging silicone rubber's flexibility and conductive materials like carbon or metal domes, meet these needs by providing:

- Durability: Resistance to extreme temperatures, moisture, dust, and chemicals.

- Tactile Feedback: Precise actuation for operators, even with gloves.

- Customization: Tailored designs for specific machinery or control panels.

- Cost-Effectiveness: Long lifespan reduces maintenance costs.

FromRubber's conductive keypads are engineered to withstand rigorous industrial conditions, ensuring operational efficiency and user satisfaction.

Key Features of Conductive Keypads for Industrial Use

Conductive keypads are designed with features that make them ideal for industrial applications. Below, we outline the most critical attributes, drawing on FromRubber's manufacturing expertise.

1. Environmental Resistance

Industrial settings expose keypads to harsh conditions. FromRubber's conductive keypads achieve IP65 or higher ratings for water and dust resistance, using silicone rubber and protective coatings like PU or epoxy.

2. Tactile Feedback and Ergonomics

Operators rely on tactile feedback for accuracy. FromRubber customizes the snap ratio (40%-60%) and actuation force (up to 500g) to ensure a satisfying “click” feel, even in high-pressure scenarios.

3. Backlighting for Low-Light Conditions

Backlit keypads enhance visibility in dimly lit factories. FromRubber employs laser-etching and translucent silicone to create precise, illuminated symbols, improving usability.

4. Conductive Materials

FromRubber offers various conductive options, including:

- Carbon pills: Cost-effective, 20-100 ohms resistance.

- Gold or copper pills: Low resistance (1-10 ohms) for high-precision circuits.

- Conductive ink printing: Flexible for custom shapes.

5. Customization

FromRubber collaborates with clients to design keypads with specific layouts, colors (RAL/Pantone matched), and legends, ensuring seamless integration with industrial equipment.

| Feature | Benefit | FromRubber's Solution |

|---|---|---|

| IP Rating | Protects against dust and moisture | IP65+ with PU/epoxy coatings |

| Tactile Feedback | Enhances operator accuracy | 40%-60% snap ratio, 50-500g actuation force |

| Backlighting | Improves visibility in low light | Laser-etched translucent silicone with LEDs |

| Conductive Material | Reliable circuit actuation | Carbon, gold, copper pills, or conductive ink |

| Customization | Matches specific equipment needs | Custom shapes, colors, and layouts |

Applications of Conductive Keypads in Industry

Conductive keypads are versatile, supporting a wide range of industrial applications. Below are key sectors where FromRubber's solutions excel.

1. Manufacturing Equipment

Conductive keypads control assembly lines and CNC machines, offering durability and precise input. FromRubber's keypads withstand vibrations and chemical exposure, ensuring uninterrupted operation.

2. Heavy Machinery

In construction and mining, keypads on heavy equipment must resist extreme conditions. FromRubber's weatherproof designs with high actuation force support operators in rugged environments.

3. Industrial Control Panels

Control panels in factories rely on keypads for user input. FromRubber's backlit keypads with custom layouts enhance usability, reducing errors in high-stakes settings.

4. Outdoor Kiosks and ATMs

Public-facing industrial equipment requires vandal-resistant, weatherproof keypads. FromRubber's silicone keypads with epoxy coatings ensure longevity and reliability.

FromRubber's Expertise in Conductive Keypad Manufacturing

As a leading conductive keypad manufacturer, FromRubber brings over 13 years of experience to deliver innovative solutions. Based in Xiamen, China, our ISO 9001:2008-certified facility produces keypads for global clients across industries. Our process includes:

- Design Collaboration: Working with clients to create custom layouts and specifications.

- Advanced Manufacturing: Using compression molding and high-temperature vulcanization for precision.

- Quality Control: Rigorous testing for actuation force, conduction resistance, and surface abrasion.

- Surface Treatments: Offering laser etching, screen printing, and protective coatings (PU, epoxy) for durability and aesthetics.

FromRubber's commitment to quality and customization ensures our keypads meet the stringent demands of industrial applications, from heavy machinery to control panels.

Case Study: A leading automation company partnered with FromRubber to design a backlit conductive keypad for a factory control panel. Our team delivered a weatherproof keypad with a 50% snap ratio and IP67 rating, reducing operator errors by 30% and extending keypad lifespan by 5 years.

Best Practices for Designing Industrial Conductive Keypads

Drawing from industry standards, here are best practices for designing effective conductive keypads, enhanced by FromRubber's expertise:

- Define Functional Requirements: Specify actuation force, travel distance, and environmental resistance. FromRubber's engineers assist in optimizing these parameters.

- Choose Conductive Materials: Select carbon pills for cost-efficiency or gold pills for low-resistance circuits, based on application needs.

- Incorporate Backlighting: Use laser-etched translucent silicone for clear visibility in low-light settings.

- Ensure Ergonomics: Design tactile feedback to suit gloved operators, with FromRubber's customizable snap ratios.

- Test Prototypes: FromRubber conducts lifetime, abrasion, and resistance tests to ensure reliability before mass production.

Why Choose FromRubber for Your Conductive Keypad Needs?

FromRubber stands out as a trusted partner for industrial conductive keypads, offering:

- 13+ Years of Experience: Proven expertise in silicone keypad manufacturing.

- Global Reach: Serving clients worldwide with reliable delivery.

- Customization: Tailored solutions for unique industrial applications.

- Quality Assurance: ISO-certified processes and rigorous testing.

Our keypads enhance operational efficiency, reduce maintenance costs, and elevate user experience in demanding industrial environments.

Conclusion

Conductive keypads are indispensable in industrial applications, providing durability, tactile feedback, and customization for manufacturing, heavy machinery, and control panels. FromRubber's expertise in designing and manufacturing high-quality conductive keypads ensures reliable performance in the toughest conditions. Ready to elevate your industrial equipment with custom conductive keypads? Contact FromRubber today for a free consultation or request a quote.