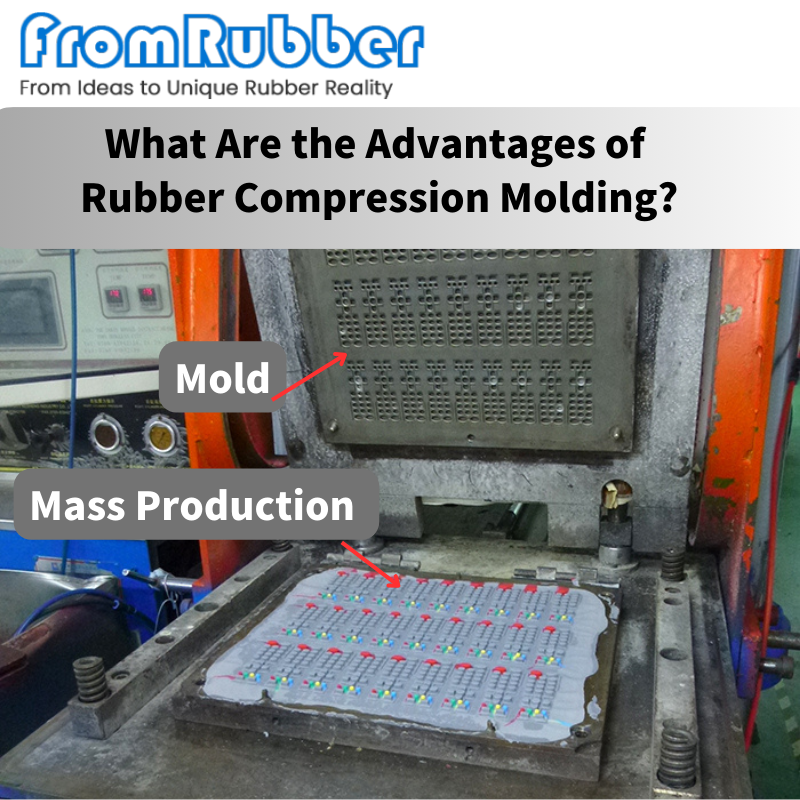

What Are the Advantages of Rubber Compression Molding?

- Share

- publisher

- karl

- Issue Time

- Oct 5,2024

Summary

Rubber compression molding offers several significant benefits, making it an attractive choice for many manufacturing needs.

Here’s why this method stands out:

1.Precision and Quality:

One of the key advantages is the ability to produce components with high precision. The parts often emerge nearly free of imperfections, allowing for speedy delivery.

2.Cost Efficiency:

The process generates minimal material waste, which translates into substantial cost savings. This efficiency can make a notable difference, particularly in large-scale production.

3.Manufacturing Simplicity

The tooling involved in rubber compression molding is generally simpler and less expensive than alternative methods. This simplicity also tends to speed up the production timeline.

4.Material Versatility

This molding technique is versatile enough to accommodate a wide range of materials. From natural rubber to silicones, like Viton, EPDM, BUNA, and neoprene, it offers flexibility to suit diverse application requirements.

By optimizing precision, reducing costs, simplifying processes, and accommodating various materials, rubber compression molding provides a comprehensive solution for rubber manufacturers looking to streamline operations and deliver quality products efficiently.