Custom Silicone Rubber Products Customization Options and Benefits

- Share

- publisher

- karl

- Issue Time

- Sep 8,2025

Summary

Discover custom silicone rubber products with tailored options in hardness\, color\, size\, and design for automotive medical and industrial applications.

1. Understanding Silicone Rubber

Silicone rubber is a versatile synthetic elastomer made from silicon, oxygen, carbon, and hydrogen. It's known for its unique combination of flexibility, durability, and resistance to extreme temperatures. These qualities make it a popular choice across many industries.

1.1 Key Properties of Silicone Rubber

| Property | Description |

|---|---|

| Flexibility | Stays soft and elastic across temperatures |

| Durability | Resists wear, tear, and aging |

| Temperature Resistance | Operates well from -75°F to over 400°F |

| Biocompatibility | Safe for medical and food applications |

1.2 Types of Silicone Rubber

There are several main types to choose from, depending on your project needs:

- ●Liquid Silicone Rubber (LSR): Highly flexible and perfect for detailed injection molding.

- ●High-Consistency Rubber (HCR): Solid form suited for compression and transfer molding with excellent mechanical properties.

Each type offers distinct benefits that impact molding, strength, and finish, making silicone rubber a reliable material for custom silicone rubber products.

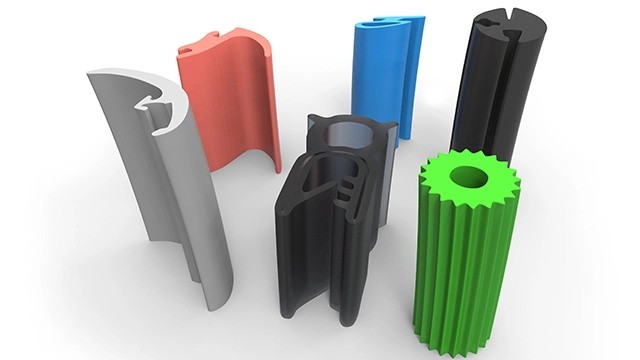

2. What Are Custom Silicone Rubber Products

Custom silicone rubber products are items made from silicone rubber that are specially designed and manufactured to meet specific needs. Unlike standard silicone parts, these products are tailored in shape, size, hardness, and other features to fit unique applications.

Common examples include:

- ●Gaskets and seals for preventing leaks

- ●Sheets cut to exact dimensions

- ●Molded parts like keypads, buttons, or protective covers

- ●Tubing for medical or industrial uses

Customization is key because it ensures the product performs exactly as required—whether that means a perfect fit, specific flexibility, or resistance to chemicals and temperatures. By tailoring silicone rubber products, manufacturers can boost reliability and lifespan, making sure each part suits its purpose without compromise.

3. Advantages of Custom Silicone Rubber Products

Custom silicone rubber products offer several clear benefits that make them a smart choice for many industries. When you tailor silicone parts to your exact needs, you get enhanced performance that off-the-shelf options just can't match.

Because these products are designed with your specific application in mind, they last longer and handle wear and tear better. That means fewer replacements and less downtime, saving you money over time.

A custom fit ensures compatibility with your machines or devices, improving overall efficiency and reducing the risk of leaks, vibration, or failure.

You also gain cost-effectiveness by choosing the right materials and designs from the start. This precision eliminates waste and avoids over-engineering, making your order more budget-friendly without sacrificing quality.

Whether you need custom silicone gaskets, seals, sheets, or molded parts, customization boosts reliability and value across the board.

4. Popular Applications of Custom Silicone Rubber Products

Custom silicone rubber products are everywhere in everyday life and industry because they offer flexibility and strength for many uses. Here are some common areas where they shine:

-

4.1 Automotive

Seals, gaskets, and vibration dampeners help keep engines running smoothly and prevent leaks or damage from heat and movement.

-

4.2 Medical Devices

Custom tubing, implants, and seals made from medical-grade silicone rubber suit sensitive health applications thanks to their biocompatibility and durability.

-

4.3 Electronics

Keypads, seals, and insulation parts in gadgets rely on silicone rubber for protection against dust, liquids, and temperature changes.

-

4.4 Consumer Goods

Wearables, kitchenware, and baby products often use custom silicone pieces because they're safe, soft, and long-lasting.

-

4.5 Industrial Machinery

Components made from silicone rubber withstand tough conditions, providing reliable seals and cushions in heavy equipment.

Each of these uses benefits from the custom fit and material options available, ensuring better performance and longer life in the US market.

5. Customization Options for Silicone Rubber Products

When it comes to custom silicone rubber products, you get plenty of ways to tailor them to your exact needs. Here's what you can usually customize:

-

5.1 Design and Prototyping Support

Work closely with manufacturers to create prototypes, making sure the design fits perfectly before full production.

-

5.2 Hardness (Durometer) Choice

Pick from a range of softness or firmness, depending on how flexible or durable you need the silicone to be.

-

5.3 Colors and Finishes

Choose from standard colors or get custom shades. Finishes can be smooth, textured, or matte to fit your style or function.

-

5.4 Sizes and Shapes

Custom sizes are standard. Complex molds and both 2D and 3D designs allow for precise shapes, no matter the application.

-

5.5 Material Additives

Additives can boost performance, such as:

- ○UV resistance to extend outdoor use

- ○Electrical conductivity for specialized parts

- ○Flame retardance for safety in harsh environments

| Customization Feature | Benefits |

|---|---|

| Design & Prototyping | Perfect fit, quicker tweaks |

| Hardness Options | From soft to firm, tailored feel |

| Colors & Finishes | Matches branding or function |

| Sizes & Complex Shapes | Fits exact machine/device specs |

| Material Additives | Enhanced durability & features |

6. Manufacturing Processes for Custom Silicone Rubber Products

When it comes to custom silicone rubber products, choosing the right manufacturing process is key to getting the quality and precision you need. Here are the main methods used in the U.S. market:

-

6.1 Injection Molding

This is ideal for producing high volumes of detailed parts quickly. Liquid silicone rubber is injected into molds, creating consistent, precise shapes—perfect for seals, gaskets, and complex components.

-

6.2 Compression Molding

Used for thicker or larger parts, this process applies heat and pressure to shape silicone rubber in a mold. It's great for durable, heavy-duty products like industrial components and custom silicone sheets.

-

6.3 Liquid Injection Molding (LIM)

LIM combines the flexibility of liquid silicone rubber with automated injection molding. It delivers tight tolerances and smooth finishes for parts like medical tubing or electronic keypads.

-

6.4 Extrusion

This process pushes silicone rubber through a shaped die to make long, continuous profiles such as tubing, seals, or custom silicone rubber strips. It's a cost-effective way to produce flexible parts with consistent cross-sections.

-

6.5 3D Printing and Rapid Prototyping

For custom silicone rubber prototypes or low-volume runs, 3D printing allows for fast design testing and adjustments. It helps speed up development for unique products before moving to full-scale manufacturing.

Each of these processes serves different needs, depending on your product's design, quantity, and performance requirements. Choosing the right one ensures you get the best results in custom silicone rubber molding and fabrication.

7. Quality Standards and Certifications to Look For

When choosing custom silicone rubber products, it's important to check for key quality standards and certifications. These ensure the products are safe, reliable, and fit for their intended use, especially in sensitive industries like medical and food.

Important certifications to consider:

- ●FDA compliance – critical for medical-grade silicone rubber parts and food-contact applications.

- ●ISO certification – ensures consistent quality management and product reliability.

- ●RoHS compliance – guarantees products are free from hazardous substances, important for electronics and consumer goods.

- Industry-specific certifications – such as ASTM or USP, which add credibility for specialized uses.

Common testing methods used to guarantee product quality:

- ●Tensile strength tests – measures how much force the silicone can handle before breaking.

- ●Tear resistance tests – verifies how well the material withstands tearing under stress.

- ●Aging tests – simulate long-term use to check durability over time and exposure to heat, UV, or chemicals.

Verifying these standards helps ensure you receive durable, safe, and high-performing custom silicone rubber products tailored to your needs.

8. How to Choose the Right Custom Silicone Rubber Manufacturer

Picking the right partner for your custom silicone rubber products is key to getting quality parts on time and within budget. Here's what to look for:

8.1 Experience and Capabilities

- ●Years in silicone rubber molding services

- ●Range of custom silicone parts they can handle

- ●Ability to work with different types of silicone rubber (liquid silicone rubber, high-consistency rubber)

- ●Access to advanced manufacturing methods like injection molding, LIM, extrusion, and 3D printing

8.2 Customization Scope

- ●Support for design and prototyping

- ●Options for hardness, colors, sizes, and finishes

- ●Ability to add material enhancements (UV resistance, flame retardants, conductivity)

- ●Flexibility with complex molds and detailed specs

8.3 Quality Control and Testing

- ●In-house testing for tensile strength, tear resistance, and aging

- ●Certifications like FDA, ISO, RoHS for medical or food-grade parts

- ●Consistent compliance with industry standards

8.4 Customer Service and Collaboration

- ●Clear communication during design and prototyping stages

- ●Willingness to adjust designs based on feedback

- ●Support through sampling and revisions

8.5 Lead Times, MOQ, Pricing Transparency

| Factor | What to Expect |

|---|---|

| Lead Times | Realistic timelines aligned with your schedule |

| Minimum Order Quantity (MOQ) | Reasonable MOQ that fits your production needs |

| Pricing | Clear quotes with no hidden fees |

Choosing a manufacturer who ticks these boxes will help you get reliable custom silicone products that fit your project needs perfectly.

9. Why Choose FromRubber for Your Custom Silicone Rubber Needs

At FromRubber, we specialize in custom silicone rubber products tailored to your exact needs. Here's why we stand out:

Expertise

- ●Years of experience in silicone rubber and plastic manufacturing

- ●Skilled team familiar with various silicone rubber molding services and fabrications

Advanced Facilities

- ●State-of-the-art injection molding, compression molding, and 3D printing technologies

- ●Capable of handling complex molds and precise silicone rubber custom manufacturing

Quality and Flexibility

- ●Strict quality control to meet FDA, ISO, and RoHS standards

- ●Wide range of silicone rubber hardness options, colors, and finishes

- ●Custom silicone gaskets, seals, sheets, tubing, and more—all made to your specs

Customer Focus

- ●Collaborative approach during design and prototyping phases

- ●Transparent pricing and reliable lead times

- ●Dedicated support ensuring every project meets your performance and budget needs

Proven Results

- ●Success stories across automotive, medical, electronics, and industrial sectors

- ●Long-term client partnerships built on trust and high-quality silicone parts

| Why FromRubber | Benefits for You |

|---|---|

| Experience | Reliable custom silicone molding and fabrication |

| Technology | High precision and fast turnaround |

| Quality | Products that meet strict safety and performance standards |

| Customization | Products built exactly to your requirements |

| Support | Clear communication & collaboration from start to finish |

10. How to Get Started With Your Custom Silicone Rubber Project

Getting started with your custom silicone rubber project is simple and straightforward. Here's how to move forward with FromRubber:

10.1 Steps to Request a Quote or Consultation

- ●Reach out through our website or call us directly to discuss your project.

- ●Provide basic details about your needs so we can tailor our response.

- ●Schedule a free consultation to review your requirements and goals.

10.2 What Information to Prepare

Before contacting us, have this ready to speed things up:

- ●Drawings or CAD files showing your desired part design.

- ●Specifications including size, hardness, color, and any special properties.

- ●Quantity of parts needed, both for initial order and future production.

- ●Any notes on application or environment where the product will be used.

10.3 Prototyping and Sampling Process at FromRubber

- ●We offer prototyping to help you test part performance before full production.

- ●Samples are made using real manufacturing processes so you know exactly what to expect.

- ●Feedback during this stage can lead to design tweaks for a perfect fit.

10.4 Timeline Expectations

- ●Initial quotes and consultations typically happen within a few business days.

- ●Prototyping and sample production can take 1–3 weeks depending on complexity.

- ●Full production lead times vary but we work with you to meet your schedule.

Starting your custom silicone rubber project with FromRubber is designed to be smooth and collaborative, ensuring your parts fit your needs and get to you on time.