A Complete Guide to Customizing Silicone Machine Gasket: How to Choose a Quality Supplier

- Share

- publisher

- karl

- Issue Time

- Apr 11,2025

Summary

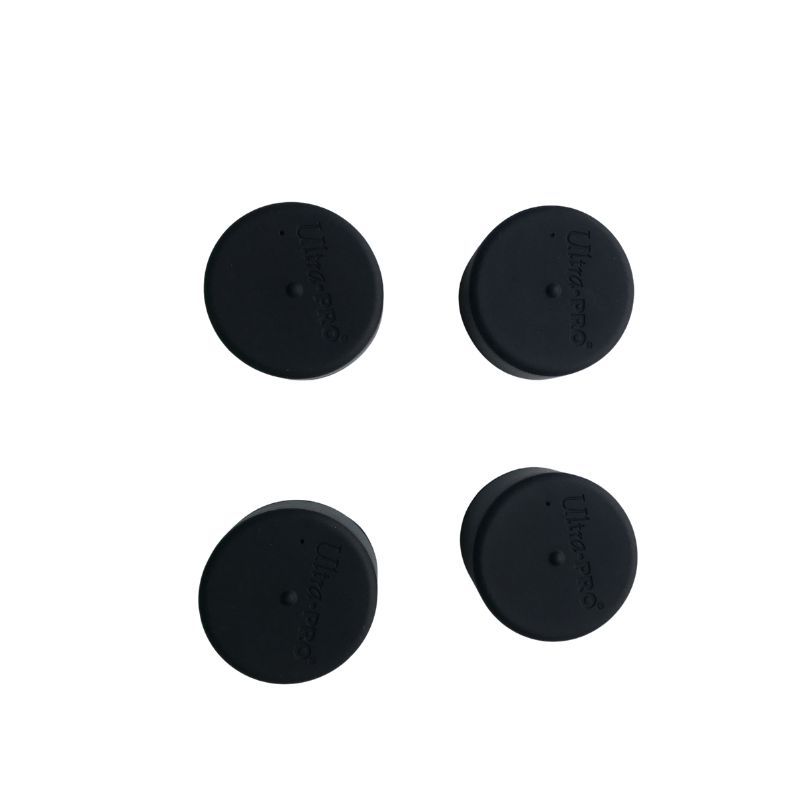

Silicone machine foot pad solutions used by global industrial equipment manufacturers! In-depth analysis of material/process/test standards, providing OEM customization full process guide.

More than 63% of industrial equipment manufacturers worldwide have experienced equipment displacement or damage due to the use of inferior foot pads. This article will systematically analyze the core advantages, selection methods and supplier screening criteria of silicone machine foot pads to help you reduce maintenance costs by more than 30%.

1. Why have silicone machine feet become an industrial standard?

1. Anti-slip performance improved by 300%

Through the diamond/wave pattern surface design, the friction coefficient of the silicone foot pad reaches 1.2 (rubber is only 0.8), successfully solving the displacement problem in high-vibration scenarios such as CNC machine tools.

2. Applicable to extreme environments of -60℃~250℃

The silica gel made by meteorological process has been tested on the high temperature platform of the injection molding machine to work continuously for 500 hours without deformation (the rubber cracks after 48 hours).

3. Shock reduction and noise reduction extend equipment life

50A hardness silicone can reduce the vibration decibel of the laser cutting machine by 18dB, and the compression deformation rate is ≤10%, preventing the loosening of precision parts.

4. Meet stringent industry certifications

Medical grade silicone has passed FDA 21 CFR 177.2600 testing, with a VOC content of <5ppm, and there is no risk of direct contact with the human body or food.

2. Four application scenarios and solutions of silicone machine feet

1.Industrial equipment: High load and oil resistant design

Case: A German CNC brand customized a cylindrical foot pad with a load-bearing capacity of 80kg/piece, with an oil-proof coating added to the surface, and the service life increased to 5 years

Parameter recommendation: Hardness 60A~70A + metal insert reinforcement.

2.Consumer electronics: balance between silence and beauty

Solution: The Bluetooth speaker base adopts two-color injection molding technology, black base + translucent anti-slip layer, Amazon user praise rate 98%

Data: When the contact surface thickness is ≥3mm, 90% of the resonance noise can be eliminated

3. Analysis of the whole process of professional silicone pad customization

The attached PDF document explains the various steps of customization in detail. If you need more detailed information, please click Contact Us

Discover our Custom Silicone Cover for HDD! Fast delivery, factory direct, tech support, and quick prototyping for retailers and wholesalers.

We provide high-quality customized silicone mats, high temperature resistant, suitable for coasters and table mats to meet your personalized needs, with preferential wholesale prices, welcome to consult!

Manufacturer FromRubber oem and odm custom waterproof and wear-resistant precision silicone rubber seals

Manufacturer FromRubber oem and odm 3M back adhesive silicone gaskets quick proofing