FromRubber Custom Abs/Pp/Pe/Nylon Plastic Seals for Household Appliance

Item specifics

- Design

- 3D Drawings or Objects

- Molding

- Injection

- Service

- Free Consult

- MOQ

- 1000pcs

- Application

- Household Appliance

Review

Description

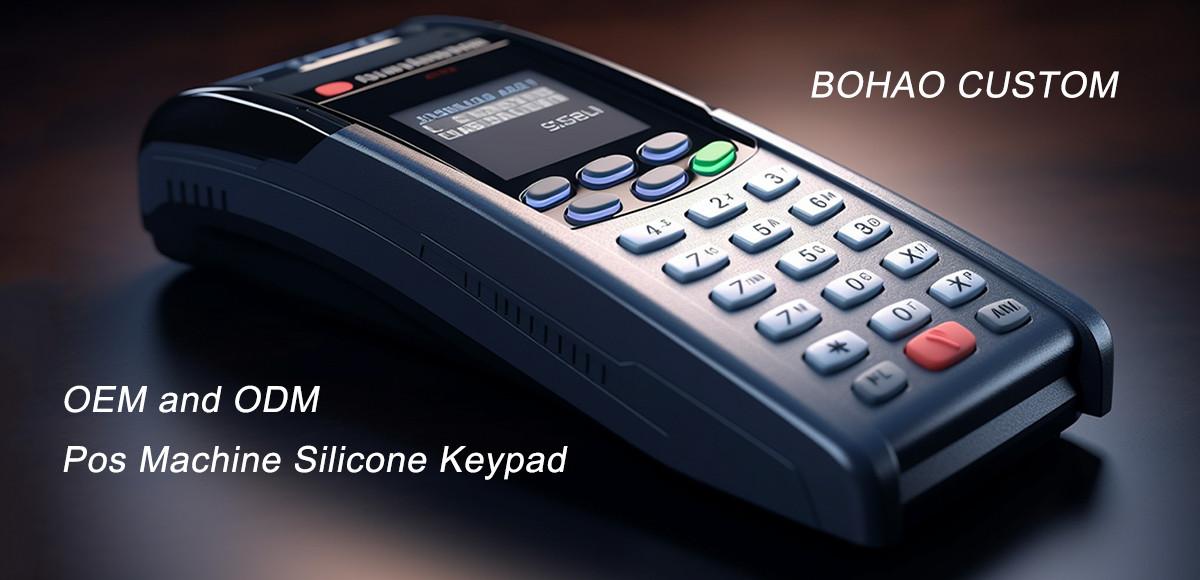

Manufacture And Design Live Streaming Equipment

Enhance Live Streaming Equipment with BOHAO's OEM/ODM Silicone Backlit Keypads - Get Rapid Prototyping and Free Technical Advice

Sillicone Conductive Keypad Compression Molding

Conductive carbon pills, small conductive elements made of carbon or graphite, are placed strategically in the silicone rubber keypad mold cavities, usually on top of the conductive traces or contacts.

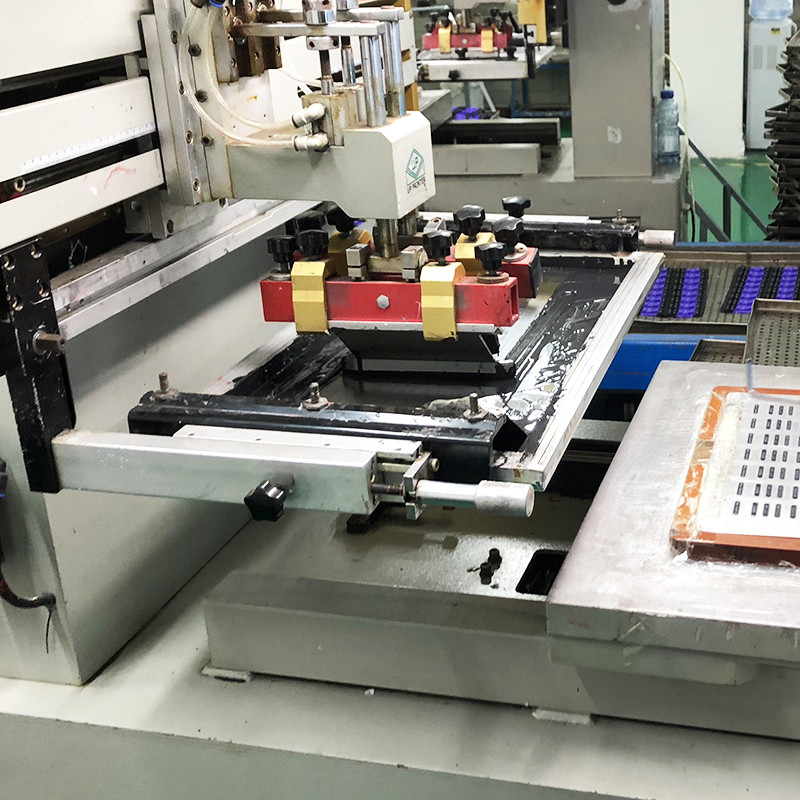

How To Silk Screen Print Silicone Conductive Keypad

Make a silk screen print stencil that matches the pattern and shape of pos machine silicone keypad.Stretch the silk screen tightly over the stencil and secure it firmly with the help of fasteners or staples.Pour a sufficient amount of conductive ink onto the mesh side of the silk screen stencil. Use the squeegee to evenly spread the ink over the design area of the stencil.Apply firm and even pressure on the squeegee while moving it across the silk screen stencil. This will force the conductive ink to pass through the mesh and apply onto the keypad surface.

Carefully lift the stencil away from the pos machine silicone keypad, ensuring not to smudge or distort the printed design.Depending on the specific type of conductive ink used, it may require curing under a UV light source or through a heat treatment.This will ensure proper adhesion and durability of the printed conductive layer.Inspect and make sure the conductive ink layer is smooth and properly adhered.