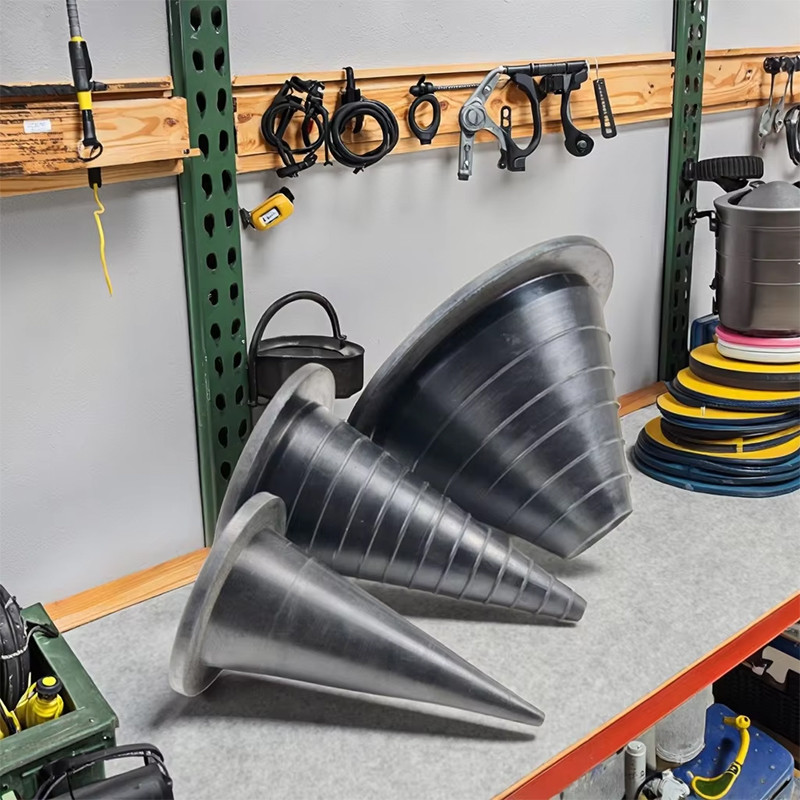

Dust-proof EPDM Rubber Conical Thread Protective Cap Tower Type Sealing

- Model

- Protective Cap

Item specifics

- Product Name

- Rubber Conical Thread Protective Cap

- Material

- EPDM Rubber

- Color

- Black

- Shape

- Customise

- Appliciation

- Factory assembly, mechanical tools,auto repair

- Features

- Dust-proof, Shockproof

- Sales Method

- Product custom

- Consultation Email

- Suey@fromrubber.com

Review

Description

FromRubber Manufacturing EPDM Rubber Products

Investment in Precision Molding & QC:

Implement strict Statistical Process Control (SPC) for dimensional tolerances (OD, wall thickness, cone angle). Guarantee batch-to-batch consistency critical.Offer custom specific EPDM rubber products.Long-Term Stability Guarantee:

Formulate EPDM specifically for excellent ozone resistance and long-term aging stability. Offer data showing performance retention (seal, elasticity) after years of shelf storage. Use packaging that minimizes light/ozone exposure during storage.Universal Fit Range Optimization:

Design EPDM rubber products with wider functional size ranges per SKU (e.g., one cap fits 1/4" NPT to 3/8" NPT) without compromising seal integrity, minimizing inventory complexity for distributors and shops. Clearly label size ranges on the epdm rubber products.The Application of EPDM Rubber Conical Thread Protective Cap

Factory assembly line

Scenario: Components (pipes, fittings, valves, hydraulic/pneumatic parts, specialized machinery shafts) move along the line before final assembly or shipment. Threads are exposed during handling, transport between stations, and temporary storage.

Use: EPDM rubber conical thread protective Cap are snapped onto exposed male threads (e.g., pipe ends, valve stems, actuator rods) immediately after machining or inspection. They stay on throughout the line until the part is ready for mating/assembly

Mechanical tool parts room

Scenario: Spare parts (pipes, fittings, bolts, specialized tool attachments, replacement spindles), often expensive or critical, are stored on shelves or in bins. They may sit unused for extended periods.

Use: EPDM rubber conical thread protective Cap are placed on all exposed male threads of stored components. They remain in place for the entire duration of storage until the part is issued for use.

Home equipment protection

Scenario: Outdoor equipment (garden hoses, pressure washers, sprinkler system fittings, BBQ propane connectors) or tools (extension wands, certain power tool attachments) have exposed threads when not connected or during storage.

Use: EPDM rubber conical thread protective Cap are placed on exposed male threads (e.g., hose ends, spray gun tips, regulator outlets) after use and before storage, especially for seasonal equipment.

Automotive repair shop

Scenario: New or refurbished parts (fuel lines, brake lines, sensors, fittings, suspension components, injectors) are handled, stored, and installed. The environment is greasy, dirty, and exposes parts to various fluids.

Use: EPDM rubber conical thread protective Cap are placed on threaded ends (e.g., brake line flares, fuel rail ports, sensor threads, shock absorber shafts) immediately upon receipt from suppliers or after refurbishment. They stay on until the moment the part is installed onto the vehicle.