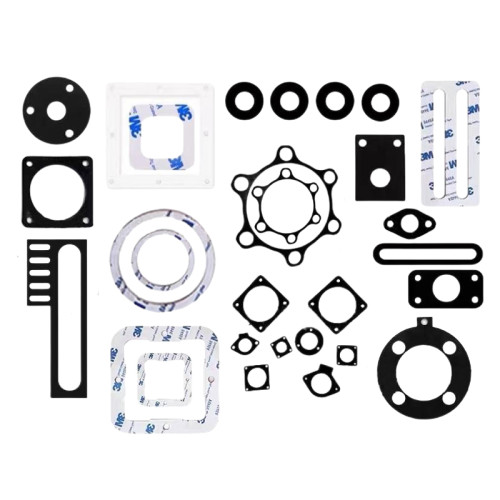

Custom 3M Back Adhesive Silicone Gaskets: Waterproof, Durable Seals for Electronics & Automotive

Item specifics

- Design

- Follow 3D Drawing Or Physical Object

- Printing

- Silk Screen Printing,Laser Etching

- Feature

- Waterproof Dustproof

- MOQ

- 1000pcs

- Application

- Electronic and electrical equipment/Automobiles

- Tape Model

- 3M adhesive series

Review

Description

1. What's the 3M Back-Adhesive silicone gasket?

2. Assembly of silicone and Adhesive

2. Assembly of silicone and Adhesive

Adhesive-backed silicone gaskets (also known as self-adhesive silicone gaskets or thermally conductive silicone gaskets) are a sealing or filling material with a silicone base and a pressure-sensitive adhesive (PSA) backing. They combine the flexibility of silicone with the convenience of an adhesive backing and are primarily used for sealing, vibration reduction, and thermal conductivity. Here are its key features:

◆ High temperature resistance and wide temperature range: It can be used for a long time in an environment of -80°C to 200°C (or higher, such as -65°C to 450°F), maintaining its softness and elasticity, and is not easy to age or deform.

◆ Good sealing and elasticity: It has high compressibility and strong resilience, can effectively fill the gaps on irregular surfaces, and is dust-proof, waterproof and vibration-proof.

◆ Chemical stability and environmental resistance: resistant to UV light, ozone, water, weathering, non-corrosive, non-toxic and odorless, physiologically inert, suitable for outdoor or harsh environments.

◆ Insulation and electrical properties: Excellent electrical insulation, suitable for electronic equipment.

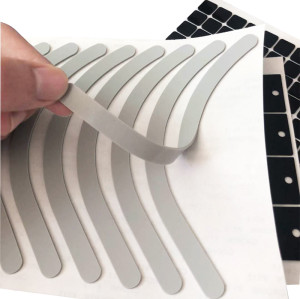

◆ Easy to install: The adhesive backing provides strong self-adhesion, no additional fixing tools are required, simplifying the assembly process and improving efficiency.

◆ Thermal conductivity (some models): After adding thermal conductive powder, it can effectively conduct heat and reduce thermal resistance, suitable for heat dissipation applications

◆ Others: low volatility, low compression force, customizable color and thickness (common thickness is 1/16 inch, hardness such as 60A Shore).

These characteristics make adhesive-backed silicone gaskets excellent in industrial applications, but it should be noted that the silicone substrate may not be suitable for certain high-mechanical stress environments.

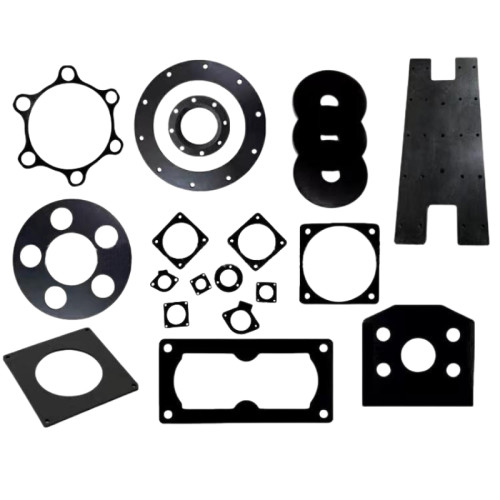

3. Application of adhesive-backed silicone gasket

Adhesive-backed silicone gaskets are widely used in applications requiring sealing, vibration damping, or heat conduction, particularly in the electronics, automotive, and home sectors. Common applications include:

◆ Electronic and electrical equipment: Used in power modules, DC-DC converters, LED lighting, onboard chargers, and network communication equipment as a thermally conductive filler, dissipating air and reducing thermal resistance while also providing insulation and vibration damping.

◆ Automotive and machinery: Used in vehicle door and window sealing, vibration damping components, automotive control units, and electrical machinery interface sealing to prevent dust and water.

◆ Industrial sealing: Used in pipe connections, equipment interfaces, and gap filling, especially in high-voltage transmission tower bases and high-voltage environments to protect against lightning strikes and vibration.

◆ Heat dissipation modules: Used to create a thermal path between heat sources and heat sinks, commonly found in consumer electronics such as computers and mobile phones.

◆ Home and construction: Used in door frame sealing, home repairs (such as fixing hooks), and building sound insulation and waterproofing, offering easy DIY installation.

◆ Medical and military: Low-emission grades are used in medical equipment and military electronics, providing a non-toxic seal.

◆ Other applications: Outdoor applications include solar equipment, vibration dampening pads, and shock-absorbing pads in gaming and multimedia devices.

The self-adhesive and versatile properties make it highly effective on assembly lines, but application requires a clean surface to maximize adhesion.

4. Common 3M adhesive classification used in silicone products

3M offers a wide variety of adhesives and tapes suitable for backing or bonding silicone products, such as silicone gaskets, seals, and foams. Because silicone surfaces are highly inert, silicone-based or combination adhesives are often used to ensure good adhesion. The following is a common classification, organized by adhesive family and type (based on acrylic, silicone, rubber, and other substrates). These adhesives are commonly used for die-cutting, double-sided bonding, or sealing silicone products:

| Classification | Common Model | Features | Typical Applications in Silicone Products |

| Silicone Adhesives | 3M 9731/3M Silicone Sealants(如08019 Marine Grade | Wide temperature range (-80°C to 200°C), UV/ozone resistant, low odor, high adhesion to silicone, combination type provides double-sided different adhesive systems (one side silicone sticks to silicone, one side acrylic sticks to other surfaces) | Silicone gasket adhesive, foam seals, marine/outdoor silicone seals, bonding silicone elastomers |

| Acrylic Adhesives | 3M 9448、3M 200MP/300LSE(9496LE)、3M 9471 | High strength, low odor, high temperature resistance, fast strength buildup, suitable for low surface energy materials such as silicone. | Silicone double-sided tape, electronic component fixation, die-cut silicone products. |

| VHB Tapes | 3M VHB series (such as 4910, 4941) | It has strong viscoelasticity, over 1000 psi shear strength, and good weather resistance, and can replace mechanical fixation. | Silicone sealing strip assembly, automotive silicone parts bonding, structural adhesive replacement. |

Rubber Adhesives | 3M Acrylic/Rubber(9817M)、3M 350/Silicone Family | Soft, fast bonding, suitable for irregular surfaces, the rubber side enhances adhesion to silicone. | Silicone shock-absorbing pads, flexible electronic silicone bonding. |

Specialty | M 5200/5200FC (polyurethane reactive type), 3M 2480/2484 (medical silicone tape) | Low volatility, skin-friendly or waterproof, suitable for medical/marine environments. | Medical silicone products, waterproof silicone seals. |

These 3M adhesives are commonly used for backing silicone products (for enhanced adhesion, use 3M Silicone Treatment Agents such as G-777). When selecting, consider temperature, surface type, and environmental considerations (e.g., low VOC). In practice, 3M 9731 is the most common combination adhesive used for silicone gaskets.

As demand for the custom 3M back adhesive silicone gaskets soared, FromRubber expanded its operations, investing in state-of-the-art manufacturing facilities and cutting-edge machinery to meet the growing needs of their customers. With a dedicated team of experts overseeing production and quality control, the company ensured that each silicone gasket was crafted with precision and care, upholding the highest standards of excellence that had become synonymous with the FromRubber brand.