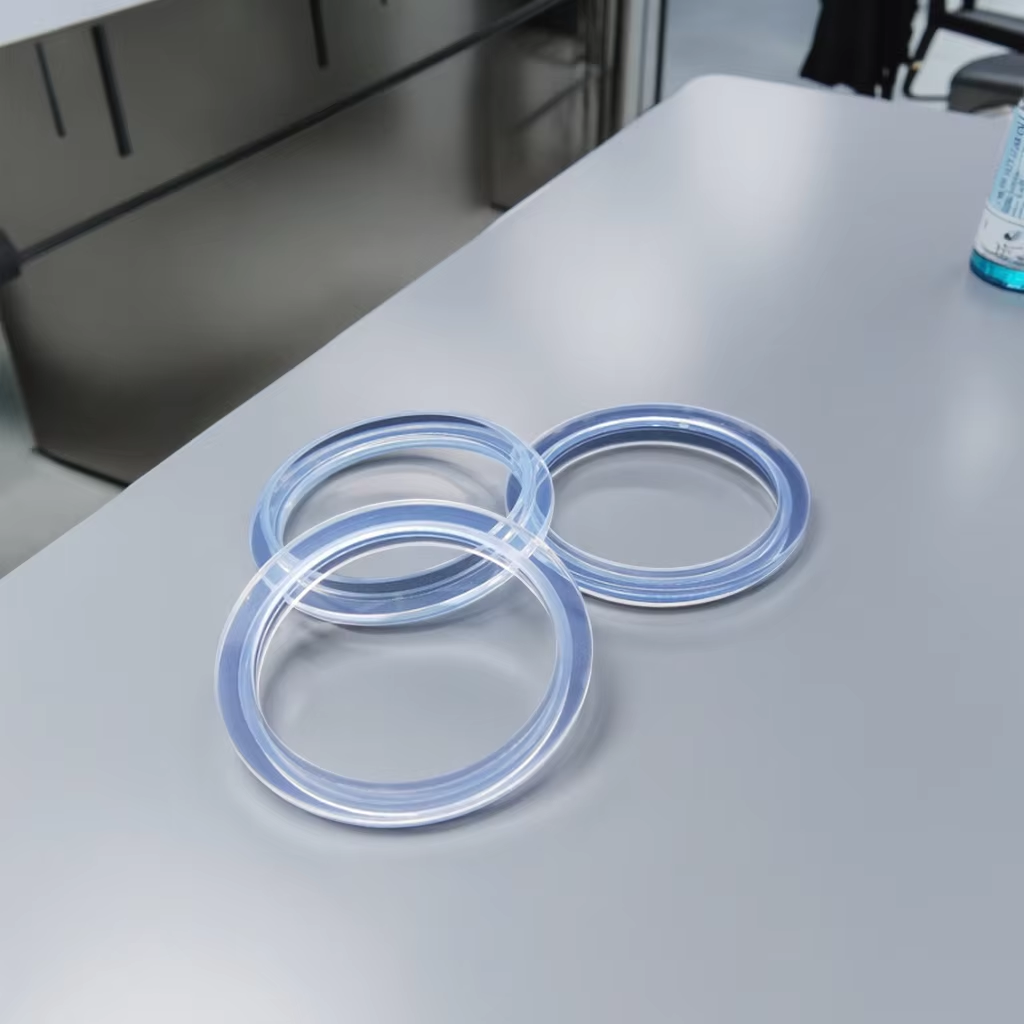

Medical Liquid Clear Silicone Cover Products for Hospital and Laboratory

- Model

- silicone Tips

Item specifics

- Product Name

- Clear Silicone Mask/Cover/Stopper/Case/Sleeve

- Material

- Medical Liquid Silicone

- Color

- Clear

- Shape

- Customise

- Appliciation

- Hospital and Laboratory

- Features

- Easy to Clean, Medical-grade, non-toxic

- Sales Method

- Product custom

- Consultation Email

- Suey@fromrubber.com

Review

Description

1.Custom Medical Liquid Clear Silicone Cover

Medical Liquid Clear Silicone Cover Functional Versatility

High optical clarity (light transmission ≥92% per ASTM D1003) enables real-time patient monitoring (e.g., CPAP mask seals).

Chemically inert (USP Class VI validated), ensuring zero drug adsorption and functionality across -50°C to 250°C, ideal for syringe check valves/aseptic container sealing.

Tear-resistant (ASTM D624 Die C: ≥45 kN/m) with cushioning performance (compression set <10% @150°C), providing IP68-rated waterproofing and dielectric insulation (18 kV/mm per IEC 60243-1) for sensitive instruments.

Medical Liquid Clear Silicone Products Clinical Applications & Functional Advantages

Respiratory Therapy Devices

Key Benefits:

Dynamic sealing maintains >95% air-tightness at 4-20 cmH₂O pressure (ISO 17510)

Transparency (≥92% light transmission, ASTM D1003) enables cyanosis detection

Skin compatibility (pH 5.5-7.0) reduces facial pressure ulcers

Pharmaceutical Containment Systems

Key Benefits:

Zero leachables (USP <381> compliant) prevents drug degradation

-50°C to 250°C stability maintains elasticity during lyophilization/autoclaving

Self-sealing property withstands ≥100 needle penetrations (ISO 8871-3)

Invasive & Implantable Devices

Key Benefits:

Biofilm resistance (Log 6 reduction per ISO 22196)

Hemocompatibility (ISO 10993-4: non-thrombogenic)

Radiolucency (absence of barium sulfate) for imaging clarity

Wearable Diagnostics

Key Benefits:

Adiabatic properties (thermal conductivity 0.2 W/m·K) prevent skin burns

Moisture vapor transmission (≥500 g/m²/day) mitigates maceration

Dielectric strength (18 kV/mm) ensures signal integrity

★Reach out anytime—we’re here to help with expert customization support!

LSR Medical Liquid Silicone Products Components

Mask/Cover

: Transparent CPAP seals enabling real-time patient monitoring

Stopper/Case: Drug adsorption-resistant (-50°C~250°C), USP Class VI compliant for syringe valves

Sleeve: Tear-resistant (ASTM D624) sheathing for endoscopes/sensors with IP68-rated protection

Certifications: FDA 21 CFR 177.2600 & ISO 10993-5/10 biocompatibility

Sterilization: >100 autoclave cycles (121°C, 15psi) or gamma irradiation compatible

Precision: 0.01mm ultra-thin molding for micro-medical devices

Key Technical Specifications of Clear Medical Liquid Silicone Products

Material Performance

Surface antimicrobial efficacy: >99.9% reduction (ISO 22196:2011)

Dielectric strength: 18 kV/mm (IEC 60243-1)

Clinical Validation

Zero extractables/leachables (ISO 10993-17)

Compression set: <10% (ASTM D395) after 500h @150°C

| Feature | Standard | Requirement |

| Biocompatibility | ISO 10993-5/10 | Cytotoxicity/Skin Irritation Class 0 |

| Transparency | ASTM D1003 | Haze ≤1.0% |

Drug Inertness | USP <87> & <88> | Non-pyrogenic, non-hemolytic |

| Tear Strength | ASTM D624 | Die C Tear ≥45 kN/m |