Custom Silicone Rubber Keypad | Push Button Supplier

- Model

- BH-Push Button

Item specifics

- Design

- Follow 3D Drawing Or Physical Object

- Printing

- Silk Screen Printing,Laser Etching

- Feature

- Backlight,Clear Character

- MOQ

- 1000pcs

- Prototype Mold Leadtime

- 3 days

- Production Mold Leadtime

- 12 days

- Production Leadtime

- 3 days

- Technical Support

- Available

- Drawing optimization

- Available

Review

Description

Custom Silicone Rubber Keypad | Push Button Supplier

1.Product Process Introduction

The product process of the silicone keypad

1. Raw material Mix: Click to learn more

The silicone raw material is a transparent color, and when black color paste is added, it mixes to become black.2. Silicone Molding: Click to learn more

The designed appearance is obtained by fixing the shape of the raw material in the mold, at which point the product is all black.

3. Printing Logo:Click to learn more

The patterns on the surface of the silicone are printed on by ink. The color of the ink is adjustable.

4. Spraying Protect Process:Click to learn more

After printing, a layer of protective oil is usually sprayed on the surface of the product to make the logo more durable.

5. Backing Adhesive Process:Click to learn more

Paste 3M adhesive paper on the back of the product with the size of the customized product all the time, note that 3M adhesive paper also needs to be customized in advance to achieve the best results.

2.Application of Silicone Keypad

●Medical industry

●Instrumentation

●Digital product

●military industry

●....

3.Advantage of Silicone Rubber

Durability

●Wear Resistance:

Excellent wear resistance for long-lasting use.

●Weather Resistance:

Resists UV, ozone, and temperature extremes, preventing aging.

Comfortable Feel

●Soft and Elastic:

Provides a comfortable tactile feel with good elasticity.

●Quiet Operation:

Low noise during use, ideal for quiet environments.

Sealing and Protection

●Waterproof and Dustproof:

Naturally resistant to water and dust, suitable for harsh environments.●Chemical Resistance:

Resistant to oils, acids, and alkalis, ideal for chemical or lab use.Design Flexibility

●Customizable:

Easily tailored in color, shape, size, and texture to meet specific needs.

●Backlighting:

Can be designed for backlighting, making them visible in low-light conditions.

Silicone rubber keypads are widely used due to their durability, flexibility, and cost-effectiveness across various industries.

4. Benefits of Gold Plated Contacts in Silicone Rubber Keypads

Gold-plated contacts in silicone rubber keypads offer a range of benefits that enhance performance and longevity. Here's why they stand out:

●Enhanced Conductivity: Gold is an excellent conductor of electricity, allowing for reliable and efficient electrical connections. This ensures that each keystroke registers accurately, crucial for devices requiring precision.

●High Current Capacity: With gold plating, contacts can handle higher levels of electrical current safely. This is particularly useful for applications that demand robust performance without compromising the integrity of the device.

●Corrosion Resistance: Unlike other metals, gold is highly resistant to corrosion and tarnish. This resistance ensures that the keypad maintains effective performance over time, even in challenging environments.

●Longevity and Durability: Gold's durability means that your keypads will have a longer lifespan. This reduces the need for frequent replacements, saving both time and resources in the long run.

●Reliable Performance in Extreme Conditions: Gold-plated contacts provide consistent performance in varying environmental conditions, such as exposure to moisture or extreme temperatures, making them ideal for diverse applications.

By incorporating gold-plated contacts, silicone rubber keypads not only perform better but also offer a more reliable, long-term solution for demanding uses.

5. Considerations for Customizing Silicone Rubber Keypads

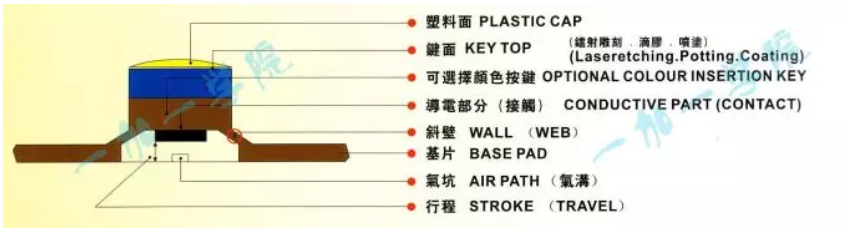

Silicone Keypad Structure Design

●The Base thickness can be taken 0.8 ~ 1.2mm, too thick substrate will increase shrinkage, affecting the dimensional accuracy.

●For conductive rubber, the stroke generally take 0.8 ~ 1.5mm is appropriate

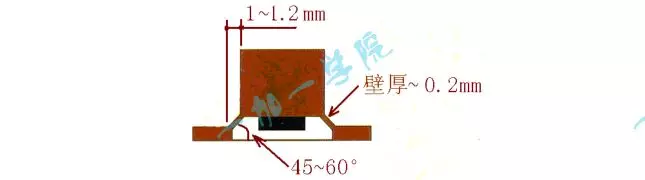

SIlicone Keypad Elastic Arms Design

Different press force according to different key sizes.In terms of area.

● 40~95mm² : 80g±15%

● 95~175mm² : 100g±15%

● 175~350mm²: 130g±15%

● 350~630mm²: 170g±15%

● 630~950mm²: 210g±15%

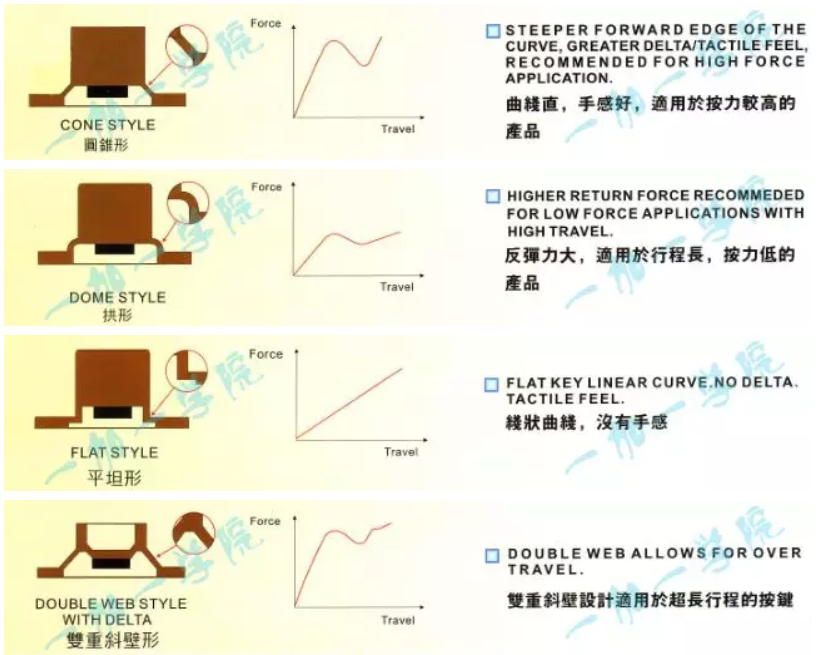

common form of Elastic Arms

●Cone Style

Suitable for products with good tactile and high elasticity

●Dome Style

Suitable for products with long stroke and low elasticity

●Flat Style

Suitable for products that do not require elasticity, commonly used in light touch switches.

●Double Web Style

Suitable for keys with very long travel

6. Commitment to Customer Satisfaction and Product Excellence

Our company is unwavering in its dedication to ensuring that every customer is delighted with their experience. We aim for perfection by consistently delivering top-tier products that align with your quality standards.

When you receive our goods, you're not just getting a product; you're obtaining a commitment to craftsmanship that enables you to confidently pass on exceptional quality to your customers. We take pride in offering items that uphold your brand's reputation as sharply as they honor ours.

By prioritizing meticulous attention to detail and comprehensive quality checks, we promise every shipment will meet your expectations, fostering a long-term partnership based on trust and satisfaction.